KURARAY LIQUID RUBBER

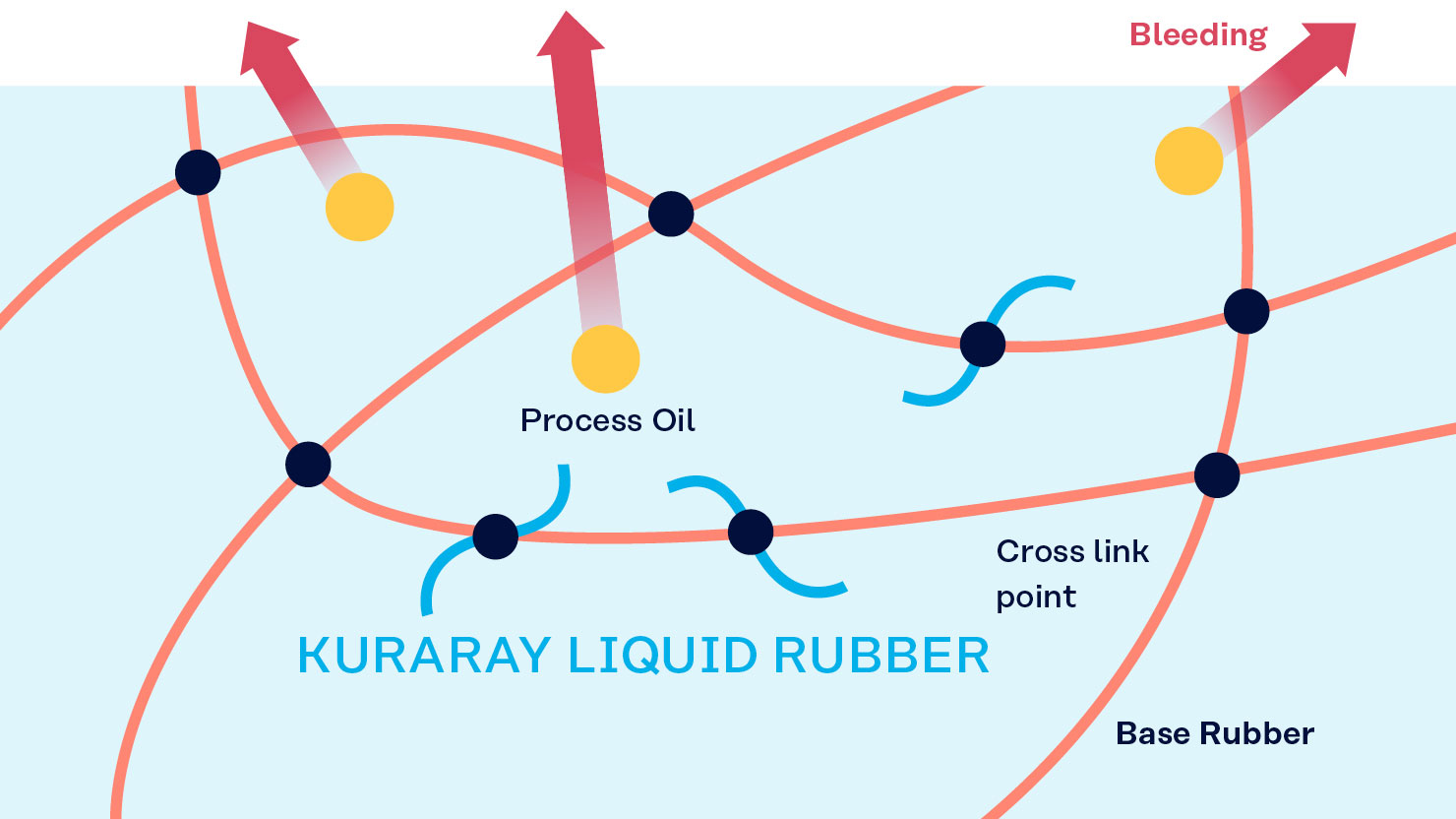

KURARAY LIQUID RUBBER products function as “reactive plasticizers”, but have much higher molecular weight than normal plasticizers. This means that in the time-consuming and labor-intensive rubber mixing process, they help reduce mooney viscosity and facilitate the mixing process. Better flowability of the compound increases the efficiency of the mixing process significantly. The physical properties of the rubber compounds are retained. Another advantage of the improved viscosity is also a longer service life of the mixing equipment, as the mixer can “stir” the compound better.

KURARAY LIQUID RUBBER includes Liquid Butadiene Rubber (L-BR), Liquid Isoprene Rubber (L-IR) and Liquid Polystyrene-Butadiene Rubber (L-SBR). The high-viscosity synthetic rubbers are colorless, transparent, almost completely odorless and have low VOC values. The polymers of butadiene, isoprene and styrene have a low molecular weight, which is designed between solid rubber and plasticizer.

KURARAY LIQUID RUBBER grades are co-vulcanizable with the base rubber to prevent migration. The significantly reduced migration massively improves the shelf life and durability of the products. Depending on the molecular weight of the grades, they can either replace part of the rubber in the formulation (high molecular weight) or replace all or part of the oil in the formulation (low molecular weight).

Content

- Features and benefits / applications

- Types of KURARAY LIQUID RUBBER

- Product brochure / technical information

- Contact

Features and benefits

- Reduces mixing time and energy consumption

- Strong tack and adhesive properties

- Low glass transition temperature (Tg)

- Rubber-like properties at low temperatures

- Colorless, transparent and low VOC

- Co-vulcanizable and reduces migration which improves the products shelf life

Applications

- Adhesives, coatings, sealants

- Electronics

- Industrial & construction

- Mobility

- Oil modification

- Rubber compounding

- Sporting goods & footwear

KURARAY LIQUID RUBBER products are used for a wide range of applications. An important area of application is tires, where KURARAY LIQUID RUBBER grades can be used for various tire compounds, including tread, carcass, sidewall and bead filler compounds.

KURARAY LIQUID RUBBER is the product of choice in the manufacture of winter tires, all-season tires and high-performance tires. It reduces Mooney viscosity, which minimizes migration while improving the workability of the rubber compound. KURARAY LIQUID RUBBER significantly improves tire performance by simultaneously managing the balance between grip, fuel efficiency and wear resistance. KURARAY LIQUID RUBBER is also popular for belts, hoses and other rubber goods.

Other applications of KURARAY LIQUID RUBBER include high-performance coatings, sealants and adhesives. In adhesives, Liquid Isoprene Rubber is used as a tackifier and plasticizer. But KURARAY LIQUID RUBBER is also used for printing plates, mortars and rubber compounding (e.g. for conveyor belts).

Kuraray has developed several high-vinyl grades for peroxide curing and Liquid Isoprene Rubber grades for EPDM applications. At the same time, the volatile organic compound (VOC) content of the products is reduced. Possible applications include sanitary components, as KURARAY LIQUID RUBBER/EPDM compounds can meet local drinking water regulations.

Types of KURARAY LIQUID RUBBER

There are three types of KURARAY LIQUID RUBBER based on the following:

- Liquid Polybutadiene Rubber (L-BR)

- Liquid Polyisoprene Rubber (L-IR)

- Liquid Polystyrene-Butadiene Rubber (L-SBR)

The types are available from low to high molecular weight variations and some feature functionalized groups.

Liquid Polybutadiene Rubber (L-BR)

Homopolymer L-BR

Homopolymer L-BR serves as a reactive plasticizer (for NR, IR, SBR, BR etc.) in the vulcanization process to prevent bleeding and migration. This type of KURARAY LIQUID RUBBER has many uses, including tires, printing plates, automotive sealants, coatings, adhesives, hot melt adhesives and pressure sensitive adhesives (PSA). It can also be used as a coagent for EPDM (peroxide curing) and for thermoset PU modification.

High Vinyl L-BR

High Vinyl L-BR are used as structural adhesives for the mobility segment (automotive exterior). The copolymers contain vinyl groups for tailored damping performance. Liquid butadiene rubber is used in high-performance, cross-linked rubber applications where high operating temperatures are common, such as hoses, seals and cables under the hood.

Kuraray has a line of high-vinyl liquid rubbers that provide two functions. First, they act as a reactive plasticizer without bleeding. Second, they improve cure kinetics similar to conventional coagents. The key advantages of incorporating liquid butadiene rubber into EPDM rubber include optimum compression set improvement, high hardness compounds, processability, low VOC levels and no migration with excellent cure kinetics.

Liquid Polyisoprene Rubber (L-IR)

Homopolymer L-IR

Homopolymer L-IR exhibits good miscibility with natural rubber and is best suited as a reactive plasticizer for NR, IR, SBR, BR, IIR, etc. These liquid rubbers are used for a wide range of applications including tire products, conveyor belts, rubber goods, pressure sensitive adhesives, hot melts, automotive sealants, coatings and adhesives. Furthermore, they are used as binders for brake pads, grinding wheels, etc.

Copolymer L-IR

Our L-IR-390 expands the use of our KURARAY LIQUID RUBBER portfolio for a wide range of automotive sealants applications. L-IR-390 is a copolymer of butadiene and isoprene and well known for its unique properties, such as:

- Low TG and good cold temperature resistance

- Unique structure provides good compatibility with BR, hydrocarbon resins and rosin resins for excellent crack resistance and damping performance.

- Unique structure provides exceptional high reactivity

Applications for Kuraray’s copolymer L-IR include hot melt adhesives, PSA (SIS, SBS and EVA based), automotive sealants, coatings and adhesives.

Liquid Polystyrene-Butadiene Rubber (L-SBR)

L-SBR has good compatibility with Solution Styrene-Butadiene-Rubber (S-SBR) and Emulsion Styrene-Butadiene Rubber (E-SBR). The material is used for ultra-high-performance tires and rubber goods, automotive sealants, coatings and adhesives, as well as damping materials.

In ultra-high-performance tires such as racing tires, L-SBR can drastically improve the wet and dry grip properties. In sealants, key features and benefits include:

- Excellent sound and vibration damping properties

- High Tan Delta over a wide temperature range

- Good reactivity

- Good expansion in foams

Functionalized Grades

Malenized L-IR (403) & Carboxylated L-IR (410)

Kuraray has developed selected copolymers with high molecular weight and different functionalities. Malenized L-IR-403 and Carboxylated L-IR-410 are carboxylated liquid isoprene rubbers (L-IR) that can improve the adhesion of rubbers to metal and the dispersion of fillers in rubbers. Applications of L-IR-403 and L-IR-410 include automotive sealants, coatings and adhesives, as well as hot melt adhesives/PSA (SIS, SBS, EVA).

Carboxyl groups generally have reactivity or affinity to polar substances, so these types are expected to have an additional function besides plasticizing effect and vulcanizability. Both types can improve the adhesion properties of rubber to various metals in addition to the reactive plasticizer function. The adhesive properties are stable even after heat aging.

UV-Curable L-IR

The field of application for UV-curable L-IR is pressure-sensitive adhesives (UV-curable adhesives). The material is characterized by good flexibility, which comes from the polyisoprene structure and, in addition to good low-temperature properties, also has a low shrinkage ratio. Moisture absorption and permeation resistance are good. In addition to its excellent adhesive properties, UV-curable L-IR also has insulating properties.

Silane-modified liquid butadiene rubber (GS-L-BR)

Silane coupling agents are used in silica-filled rubber compounds to increase filler-polymer interactions and lower the filler-filler interactions.

In addition, silane functionalized low molecular weight ‘liquid’ polymers can be used. Our silane-modified GS-L-BR is one of the latest development of functionalized liquid rubber grades.

Silane-modified groups enhance the rubber interaction with silica (which is a popular filler for tires) and improves its dispersion. Applied in tires, GS-L-BR improves the grip performance, rolling, and abrasion resistance, which has an overall positive impact on the lifetime of tires. Improved silica dispersion is a crucial success factor for overall tire performance.

Product brochure

KURARAY LIQUID RUBBER

Technical insights

You can find more information about our products and applications in the R&D documentation.

Liquid farnesene rubber (L-FR)

Liquid farnesene rubber (L-FR) expands Kuraray’s range of liquid rubber materials with a product based on natural and renewable raw materials. It contains a polymerized form of beta-farnesene, a renewable monomer. Through established fermentation processes, proprietary yeast strains convert sugar sources such as sugar cane into beta-farnesene.

L-FR is a popular ingredient in the manufacture of high-performance tires. The polymerized form of the bio-based farnesene has unique properties. Its viscosity is much lower compared to current liquid isoprene rubber. As an additive in rubber compounds, it gives them high plasticity. It maintains excellent flexibility even at low temperatures and improves ice grip.

Thanks to its optimal molecular weight, L-FR reacts completely with solid rubber during vulcanization; unlike an oil, which migrates to the surface of the rubber over time, hindering curing, it remains bound. Therefore, the performance of the tire is maintained in the long term.

Contact