Injection molding

Injection molding is a widely used manufacturing process for producing plastic parts in large quantities. The process involves using an injection molding machine to melt the material, inject it into a mold under pressure, and produce components of the desired shape after cooling.

A large portion of plastic parts in daily life are injection molded. These parts include items such as toothbrushes, car parts and housings of kitchen appliances.

Injection molding is popular due to its low unit cost and ability to manufacture complicated shapes with consistent quality. Plastics, primarily thermoplastic polymers, are used as the raw material which can be colored or filled with additives.

A high degree of design flexibility is needed. Compared to other manufacturing processes like CNC machining, injection molding enables a significantly greater variety of surface textures and materials.

Injection molding equipment

On the technical side, the injection molding process requires an injection molding machine and a mold specifically made for the part to be produced.

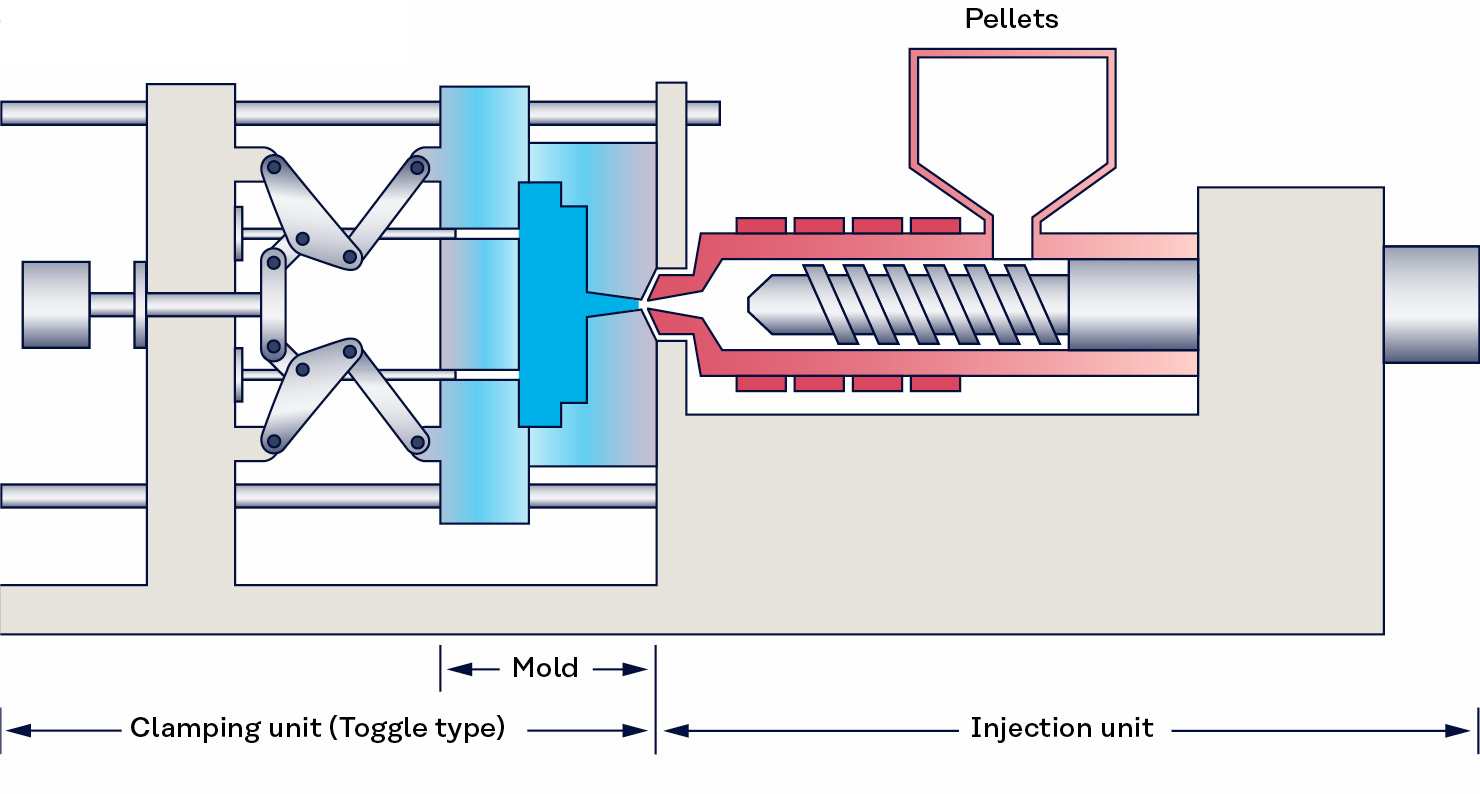

Injection molding machine

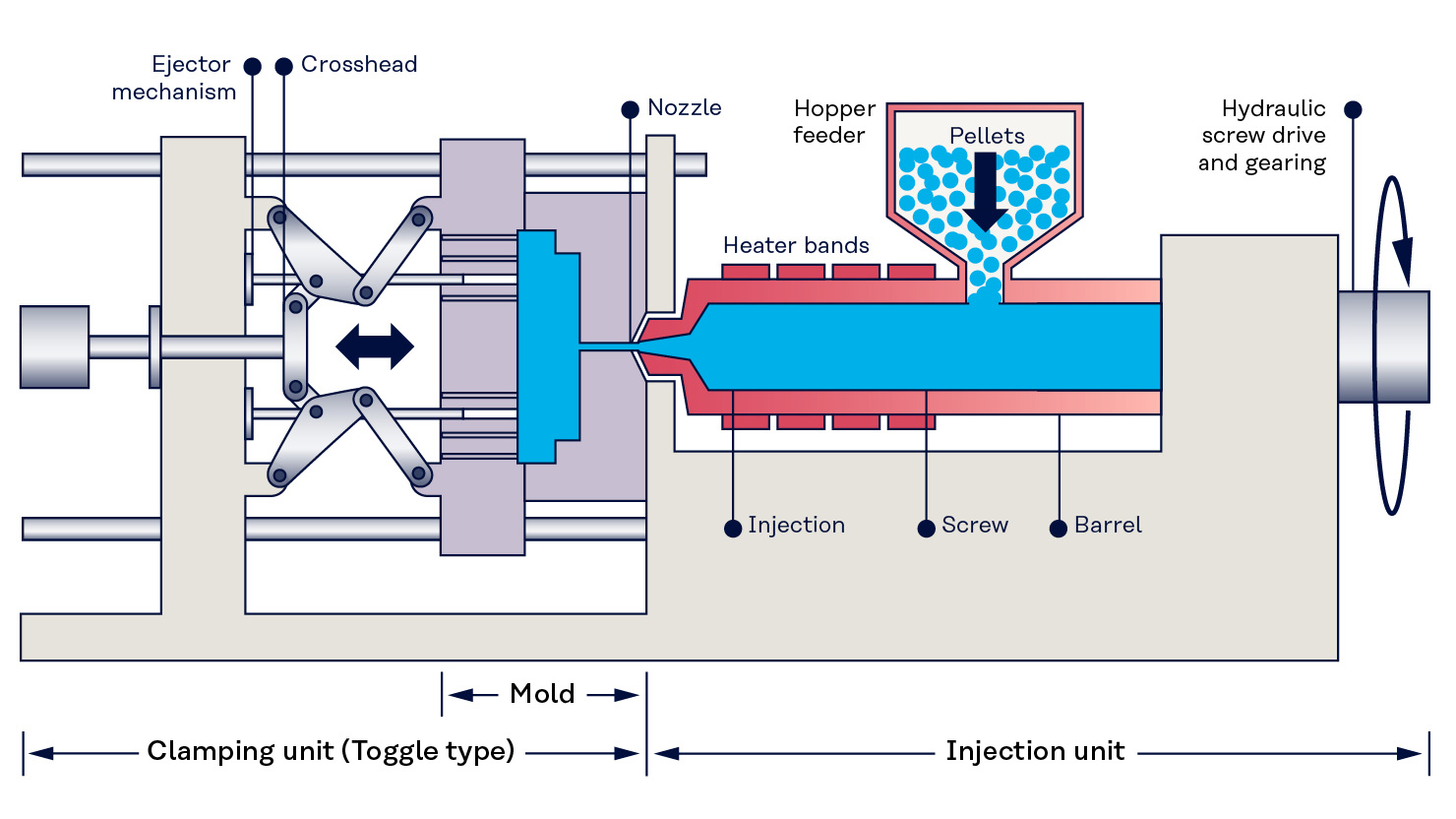

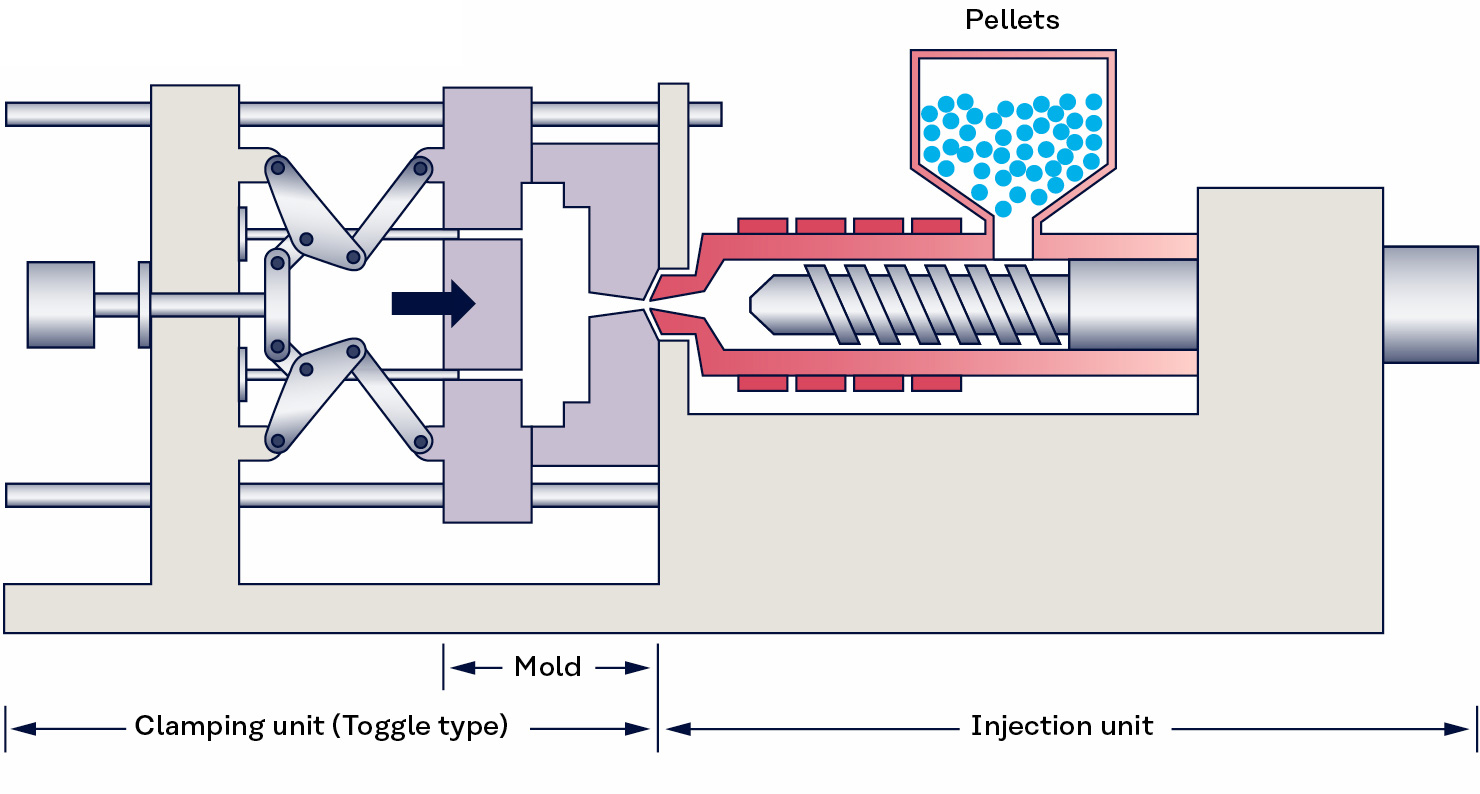

An injection molding machine consists of three main parts: the injection unit, the mold, and the clamping or ejection unit.

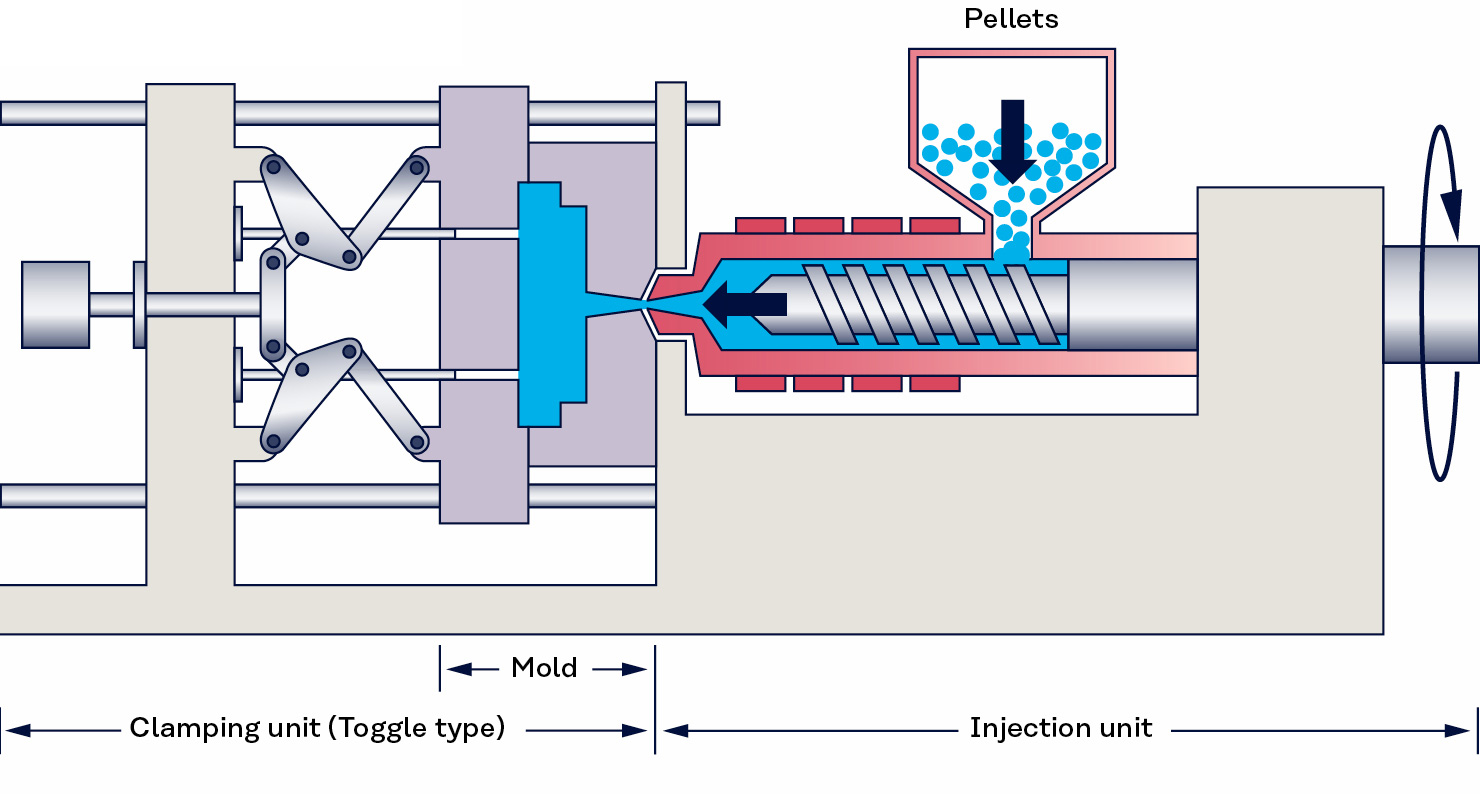

Within the injection unit, a hopper feeds the plastic into an injection ram or screw-type plunger and heating unit. Once the required amount of molten plastic has accumulated, the injection process is started.

The material is melted by heat/shear and injected into the mold with high pressure. There, the injection molded parts are formed.

The clamping unit or ejection unit has the task of opening and closing the mold and ejecting the molded products. Toggle type clamping units are the most common which consist of platens to hold the mold. These platens, usually arranged vertically on the frame of the injection molding machine, can be compared to an internal press that exerts a strong clamping force. Alternatively, straight-hydraulic type clamping units use a hydraulic cylinder to exert the clamping force on the mold.

Clamping force

The clamping force can range from a few tons to several thousand tons. Because of this wide spectrum, presses are commonly classified by their tonnage, which indicates the clamping force that the machine can exert. The required tonnage to mold a specific part depends on its projected area.

The rule of thumb is usually 5 tons per square inch for most products. However, exceptions apply for very stiff plastic materials as they require a higher injection pressure and clamping force to keep the mold closed. Larger parts also require a higher clamping force.

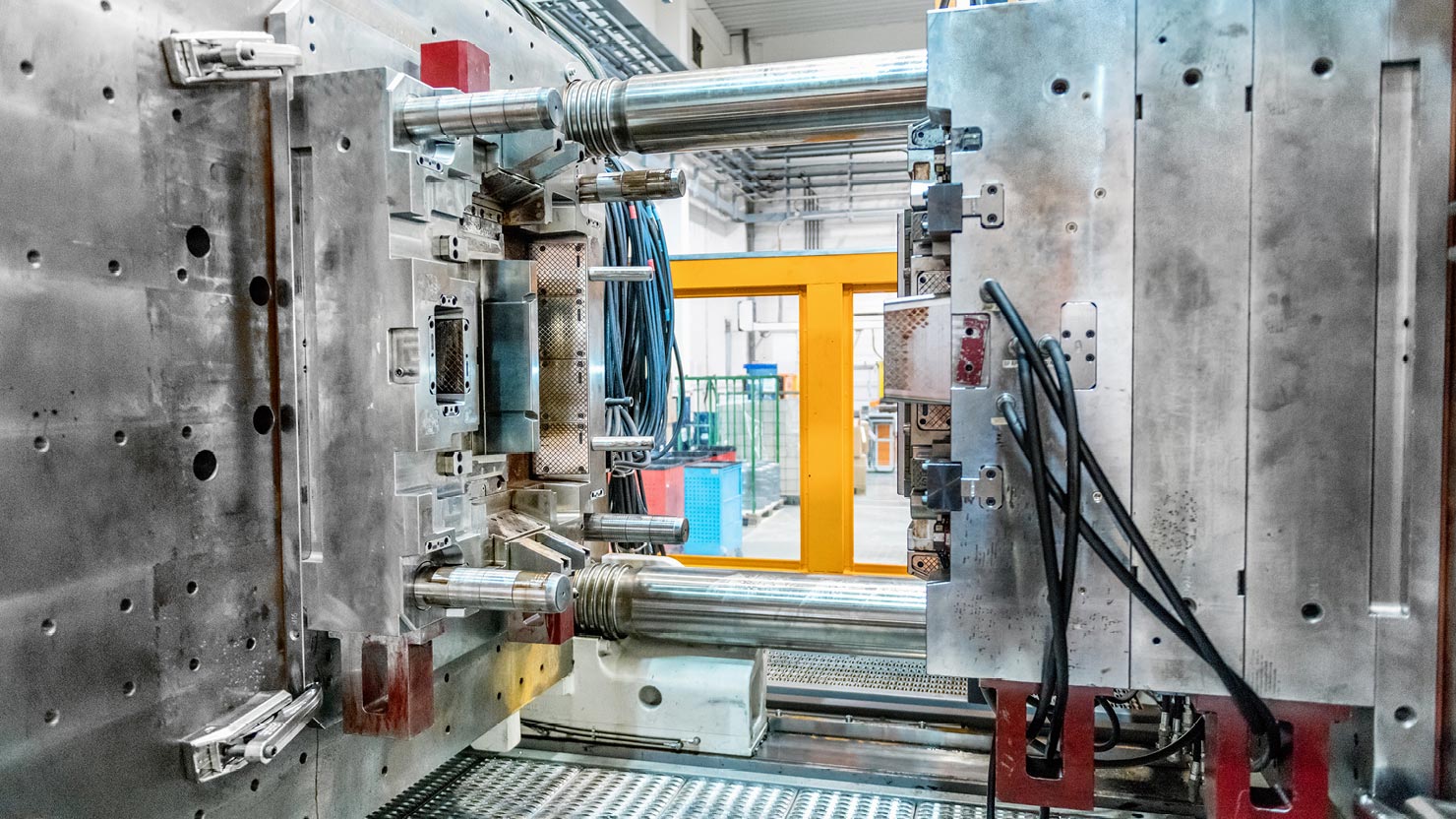

Mold

The mold, sometimes simply referred to as “tool”, is the heart of the entire process. It is a hollow metal block into which the molten plastic is injected to create the desired shape. The mold has many holes in it for temperature control and venting. Temperature is controlled using water, oil or a heater.

In its simplest form, the mold consists of two halves:

- The cavity (the front) and

- the core (the back).

Conversely, injection molded parts usually have two sides:

- The A-side of the part, usually the more visually appealing one, faces the cavity.

- The B-side, also called the functional side, usually contains the hidden structural elements of the part. Its surface is therefore often rough and shows traces of the ejector pins.

The molten plastic flows through a sprue into the mold and fills its cavities. After cooling and solidification, which usually account for about half of the injection molding cycle, the mold is opened and the molded parts are ejected.

Good to know

Molds are expensive to manufacture and for this reason are used for mass production of thousands up to millions of parts. They are typically made of hardened or pre-hardened steel, but can also be made of aluminum and/or a beryllium copper alloy.

Mold material

Steel molds are more expensive to produce, but also last longer. If a greater number of parts can be produced, the cost of the steel mold can justify the added cost. Hardened steel molds are superior in wear resistance and durability. Pre-hardened steel molds are less wear resistant and used for lower quantities or larger parts.

The less expensive aluminum molds can be economical for manufacturing tens or even hundreds of thousands of parts. Beryllium copper alloy is used where rapid heat dissipation is required or where high shear heat is present.

Mold design

The mold can be compared to the negative of a photo, where the surface structure and geometry of the mold is transferred to the finished part. It also includes features such as the gating system for material flow and internal cooling channels.

To produce thousands or even millions of parts with precision and repeatability, mold makers need an enormous amount of expertise. That’s because a mold can be very complex with various consideration such as wall thickness, corners, ribs, undercuts and threads. The high development effort is also the reason why the mold usually accounts for the largest part of the start-up costs in injection molding.

The cost of molds can vary greatly: Straight drawn molds with simple geometries for small production runs are relatively easy to develop and cost a few thousand dollars. More advanced molds for large-scale production and with complex geometries come at a much higher cost because they require retractable cores or inserts. These movable elements are inserted into the mold from above or below to produce parts with overhangs, such as an opening or cavity.

Mold design is often done in-house by machine manufacturers or specialized companies and requires consideration of raw materials and the use of finite element analysis. Moldmakers, or toolmakers, make the molds from metal, usually steel or aluminum, and precisely CNC mill them to shape the desired features. Recent advances in 3D printing materials allow for the production of molds for smaller batches at a lower cost compared to traditional methods.

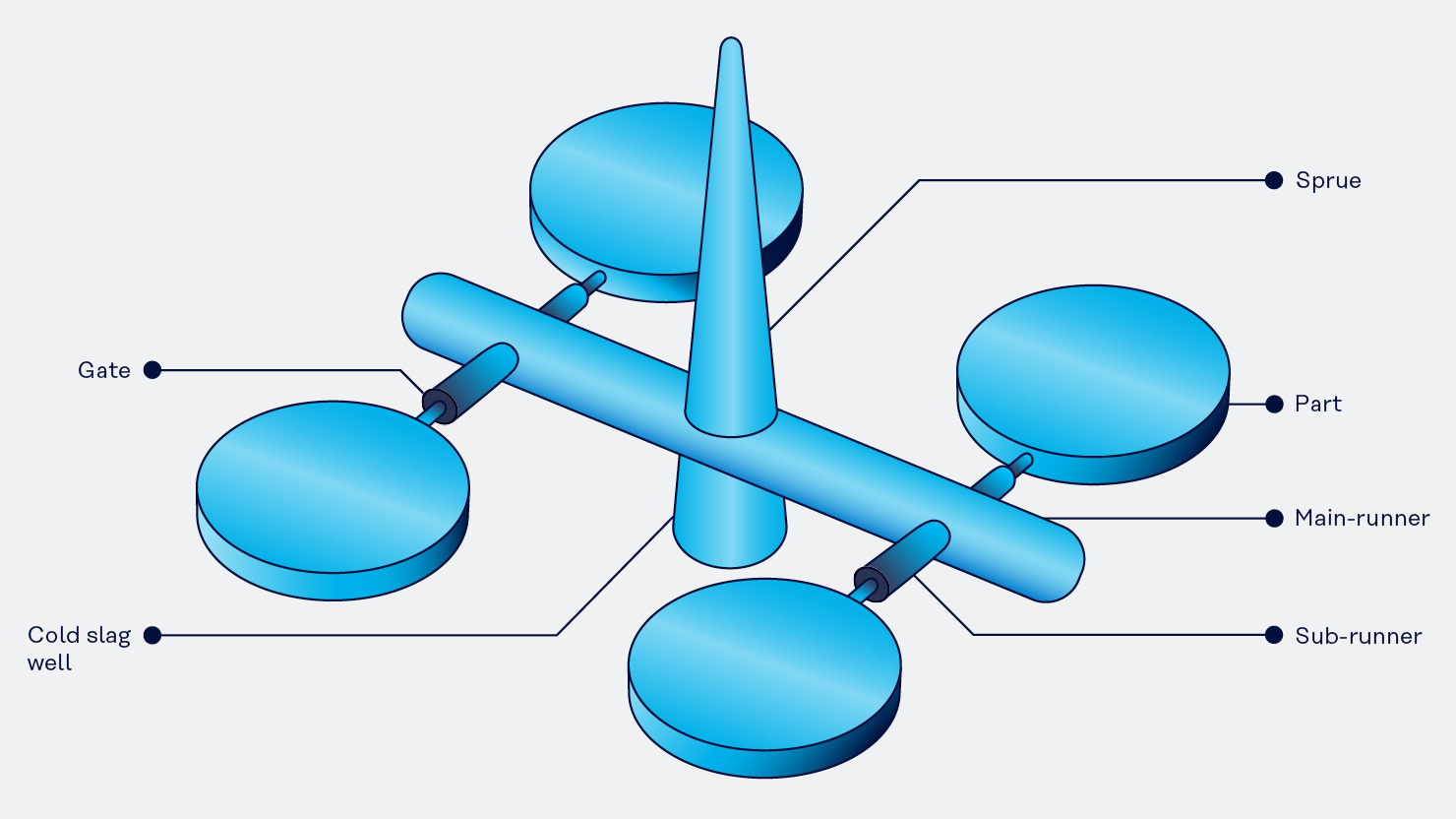

The gating system, also known as runner system, controls the flow and pressure and funnels the molten plastic into the mold. The molten plastic flows through the following channels as it enters the mold:

- The sprue,

- the main runner,

- the sub-runner and

- the gate or “feeding port”, which is the narrow channel between the sub-runner and the mold cavity.

In addition, a cold slag well commonly collects the cold slag in the injection molding process to prevent a blockage in the sub-runner or gate, so that the remaining hot material can flow into the mold cavity without complications.

The production of multiple parts often requires multiple sprues. The sprue systems are separated from the parts after ejection. Injection molding is a low-waste manufacturing method, with the sprue systems being the only material waste. A portion of this waste can even be recycled or reused, depending on the material.

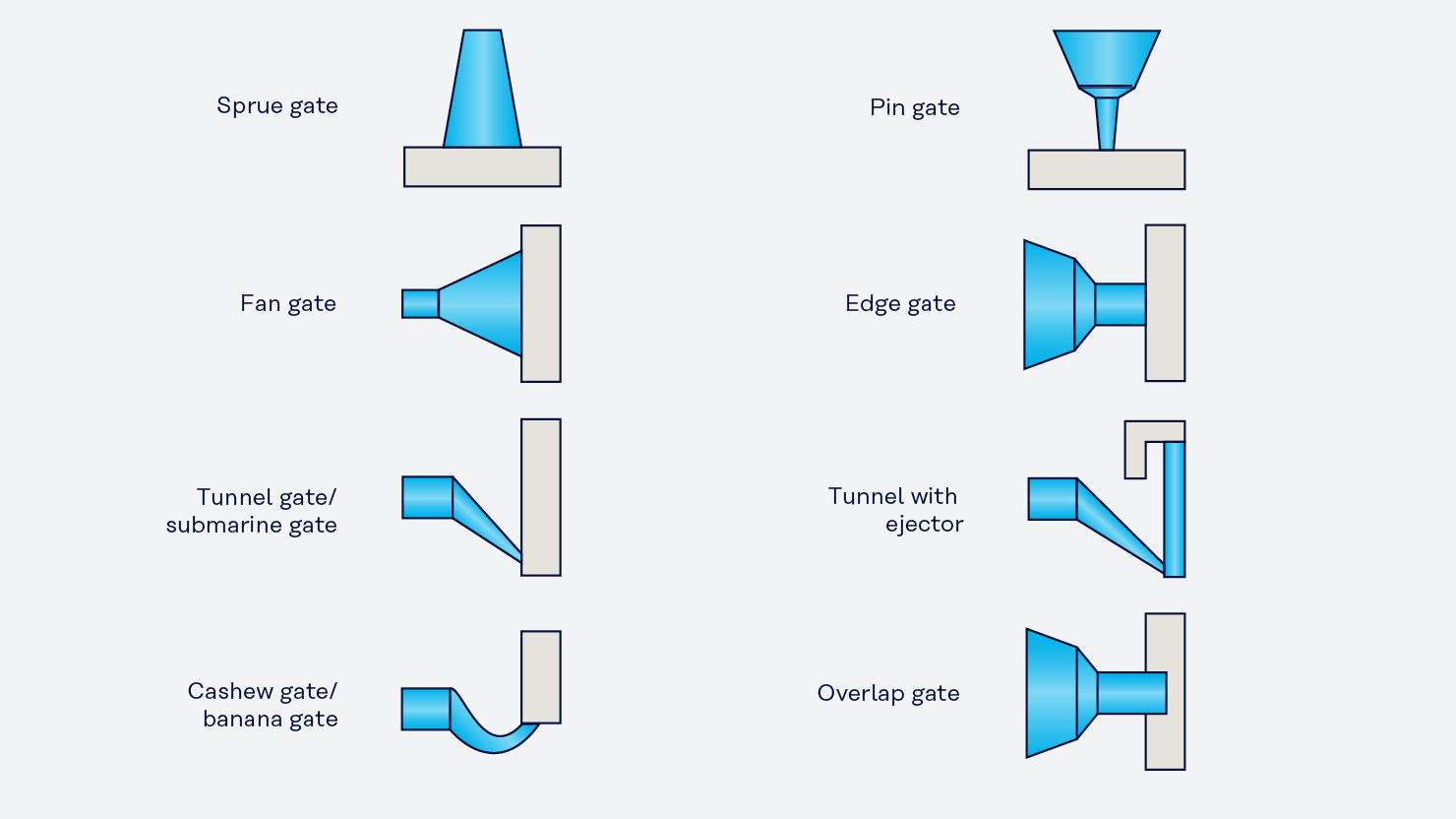

Mold makers can choose among several types of gates depending on various considerations, such as part orientation (A-side vs. B-side), ease of mold production, material selection, material flow, part size, trimming behavior and scrap cost. For more information, refer to the injection molding gating guide by Basilius.

Molds also include a closing system with two main purposes:

- Keep the two parts of the mold firmly closed during injection and

- push the injection molded part out of the mold after opening.

The ejected part then falls onto a conveyor belt or into a container and is stored or assembled.

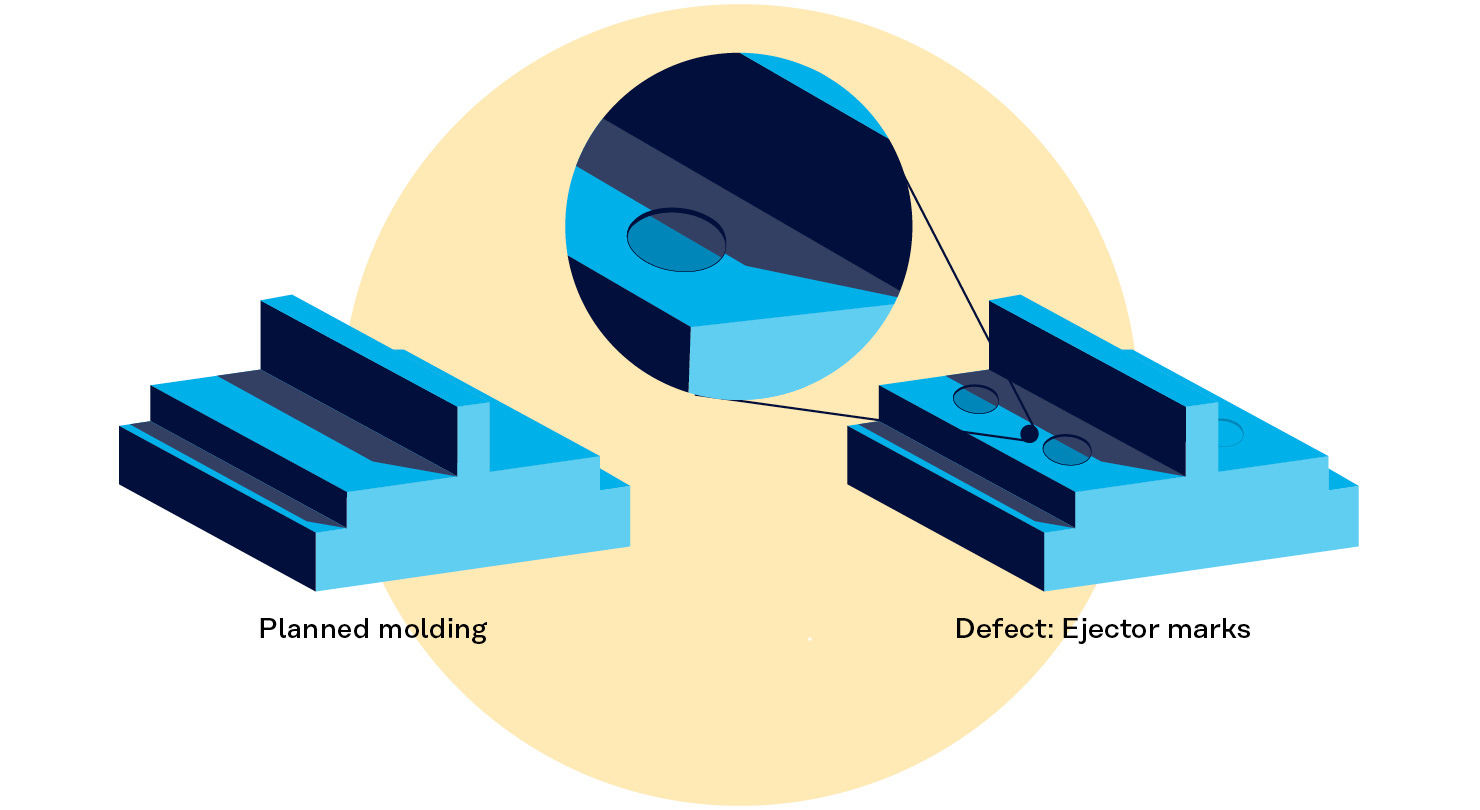

Because the various moving parts of the mold can never be aligned 100 percent, two defects can be seen on almost every injection-molded part:

- Parting lines, which are visible where the two halves of the mold meet, and

- ejector marks, which are caused by the ejector pins.

Molding

The term “molding” refers to the material filling the sprue, the cold slag well, the runners, the gates and the section of the mold cavity that forms the parts all combined.

Depending on the material, the contents of the sprue, cold slag well, runners and gates may be discarded – or reground and reused in another injection molding cycle.

Process characteristics

The process cycle for injection molding is very short and takes between a few seconds and two minutes, depending on the size of the part. The process can be divided into four main steps: Clamping, injection, cooling and ejection.

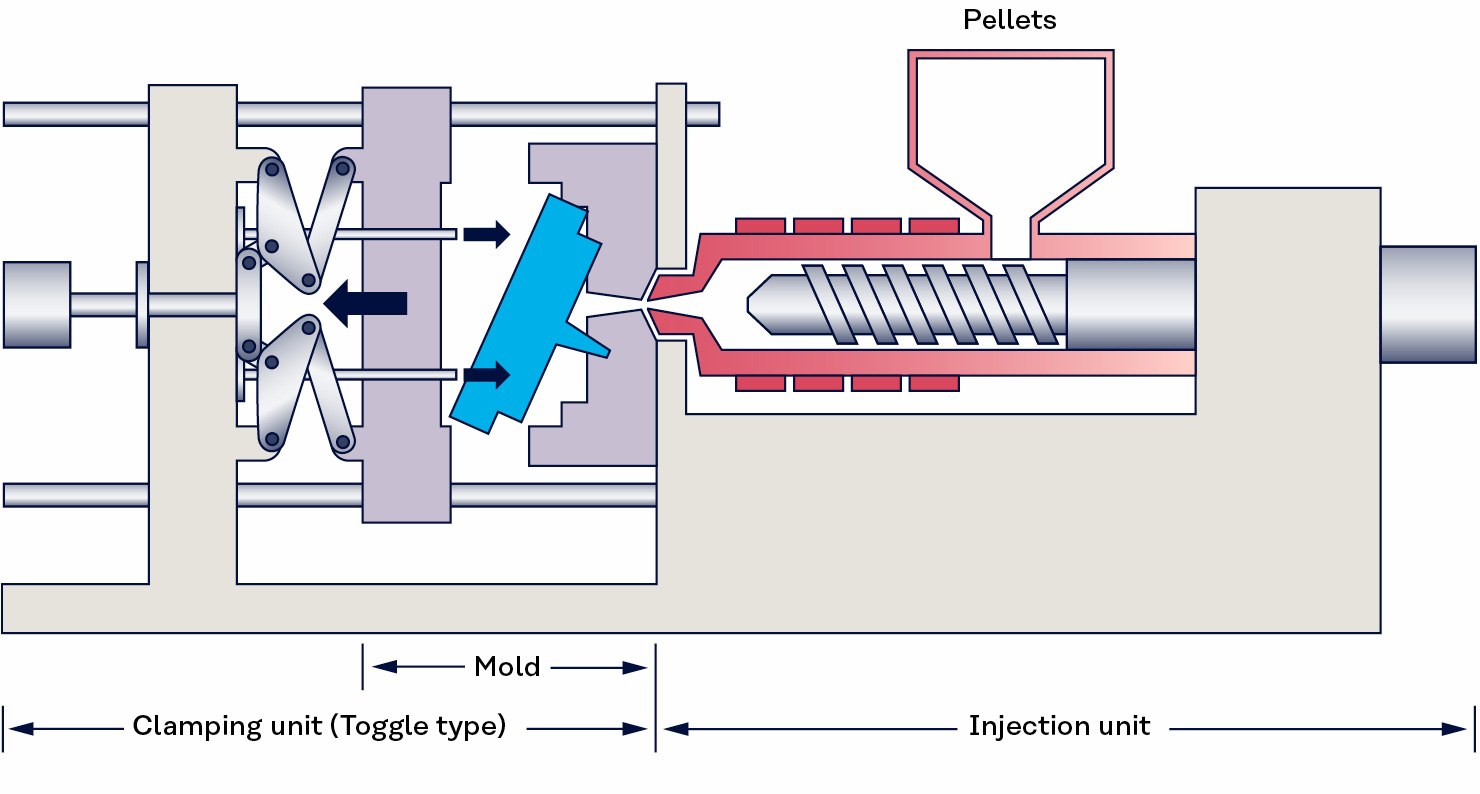

Step 1: Clamping

Before the material is injected into the mold, the two halves of the mold must be securely closed by the clamping unit. The clamping unit presses the mold halves firmly together while the material is injected. Larger machines with higher clamping forces require more time to close.

Step 2: Injection

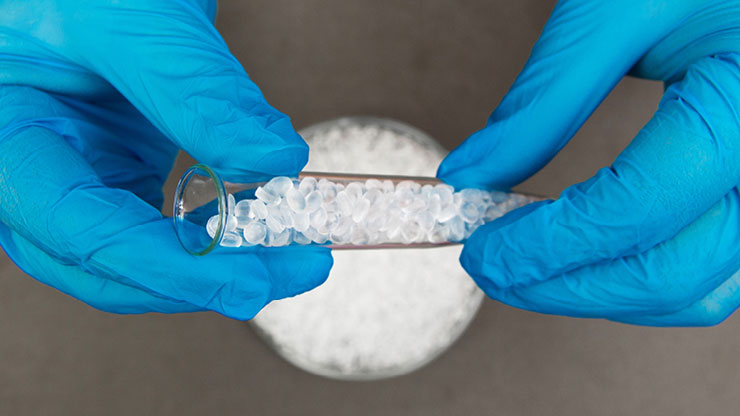

The raw material, usually plastic granules, is conveyed from the injection unit to the mold, thereby it is melted by heat and pressure. The molten plastic, the shot, is then injected through the sprue system into the mold, where it fills the entire cavity.

Step 3: Cooling

In the mold, the molten plastic begins to cool as soon as it comes into contact with the inner mold surfaces. When the material cools, it solidifies again and takes shape. The mold remains closed until the required cooling time has elapsed.

Step 4: Ejection

The cooled part is ejected from the mold using the ejector system: When the mold is opened, the molded part is pushed out of the mold by a mechanism. Depending on the gate design, the part is either separated automatically from the rest of the molding, or by cutting.

After ejection, a conveyor belt moves the molded part to storage, assembly or post-processing. Simultaneously, the mold is closed again for the next shot and the injection molding process is repeated. In some cases, the injection molded parts are ready for immediate use, while others require varying degrees of post-processing.

Types of injection molding

Traditional vs. decoupled injection molding

In traditional injection molding, the injection is performed at a constant pressure to fill and compress the cavity of the mold. However, this could result in the dimensions of the moldings varying greatly from cycle to cycle.

In decoupled injection molding, the injection process is separated into two stages for increased control of part dimensions and shot-to-shot consistency:

- Fill the cavity to about 98% using speed control, then

- fill the remaining 2% using pressure control.

Decoupled injection molding is also called scientific injection molding.

Single-component and multi-component injection molding

In the injection molding of plastics, a distinction is made between single-component and multi-component injection molding. Depending on the number of materials used, multi-component injection molding is differentiated into 2K injection molding, 3K injection molding, etc.

2K refers to two-component injection molding, where a soft material (e.g. TPE) is molded around a hard material (e.g. PP). 3K is similar to 2K, but with an extra layer or component.

Possible defects

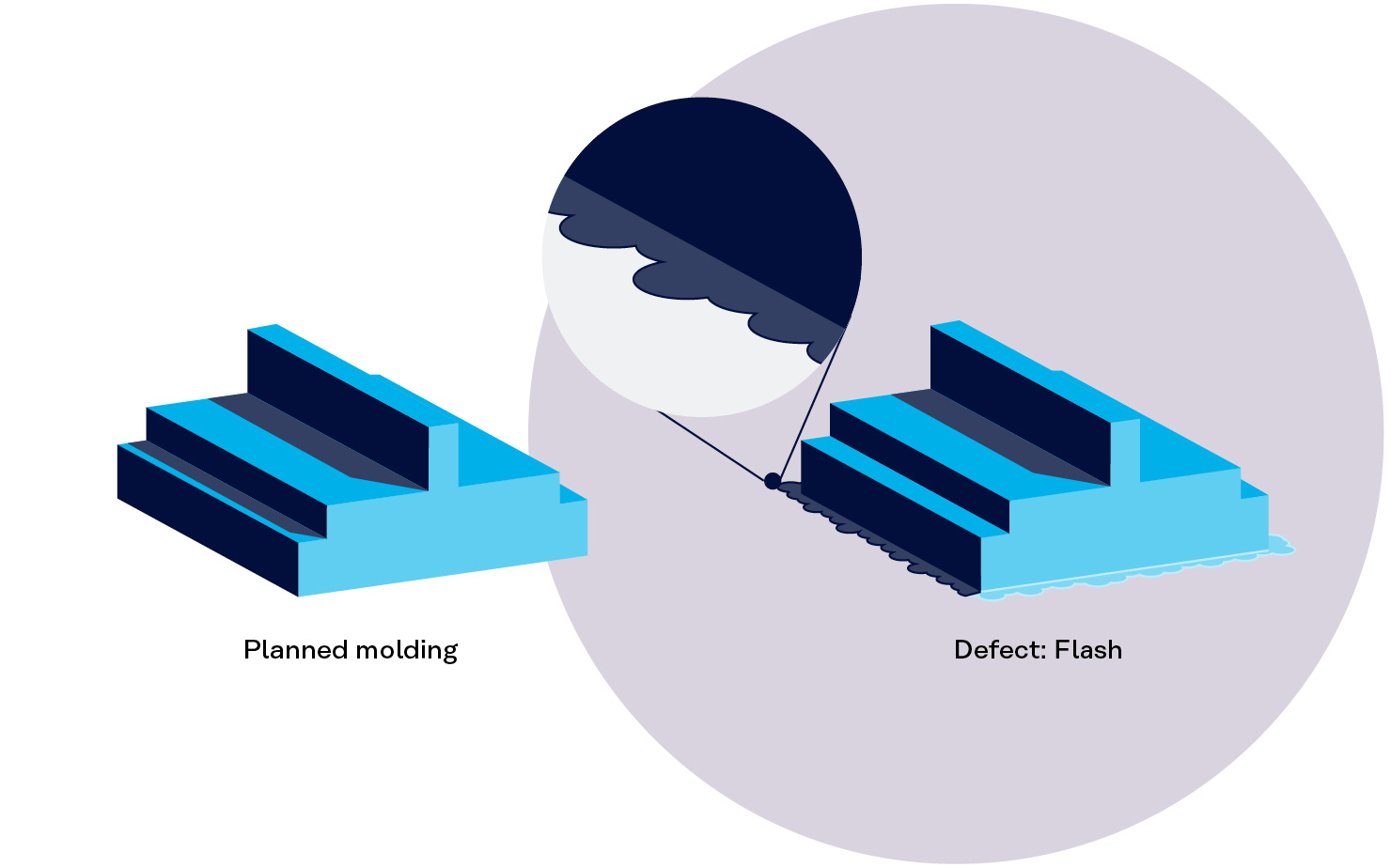

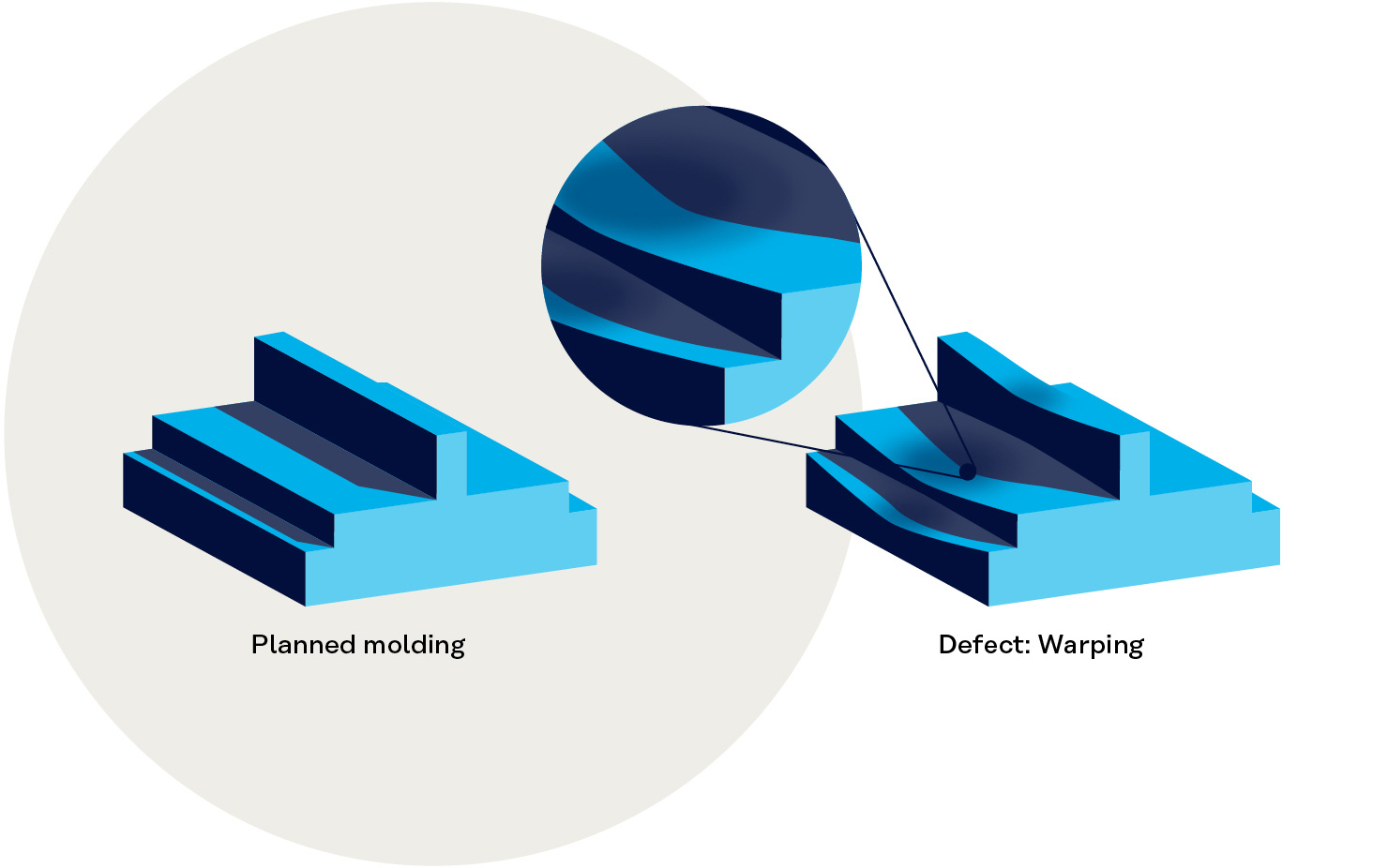

Various defects can occur in the injection molding process: machine-dependent or material-dependent defects as well as defects that can be both machine-dependent and material-dependent.

The following section is an attempt to somewhat categorize defects and present examples. In practice, there are so many possible causes of molded part defects that it is unrealistic to describe them all in a written article.

Equipment-dependent defects

Equipment-dependent defects are due to technical reasons. For example, excess molten material can escape from the mold if the injection pressure is too high or the clamping force of the mold is too low, a defect called flash or flashing.

Uneven cooling can cause parts to warp. If the mold design or the molding process do not correctly account for the shrinkage that normally occurs during cooling, parts can warp.

Bubbles on the molded parts appear when the mold or the material are too hot. This defect is usually machine-related and caused by a lack of cooling around the mold or a heater not working as intended.

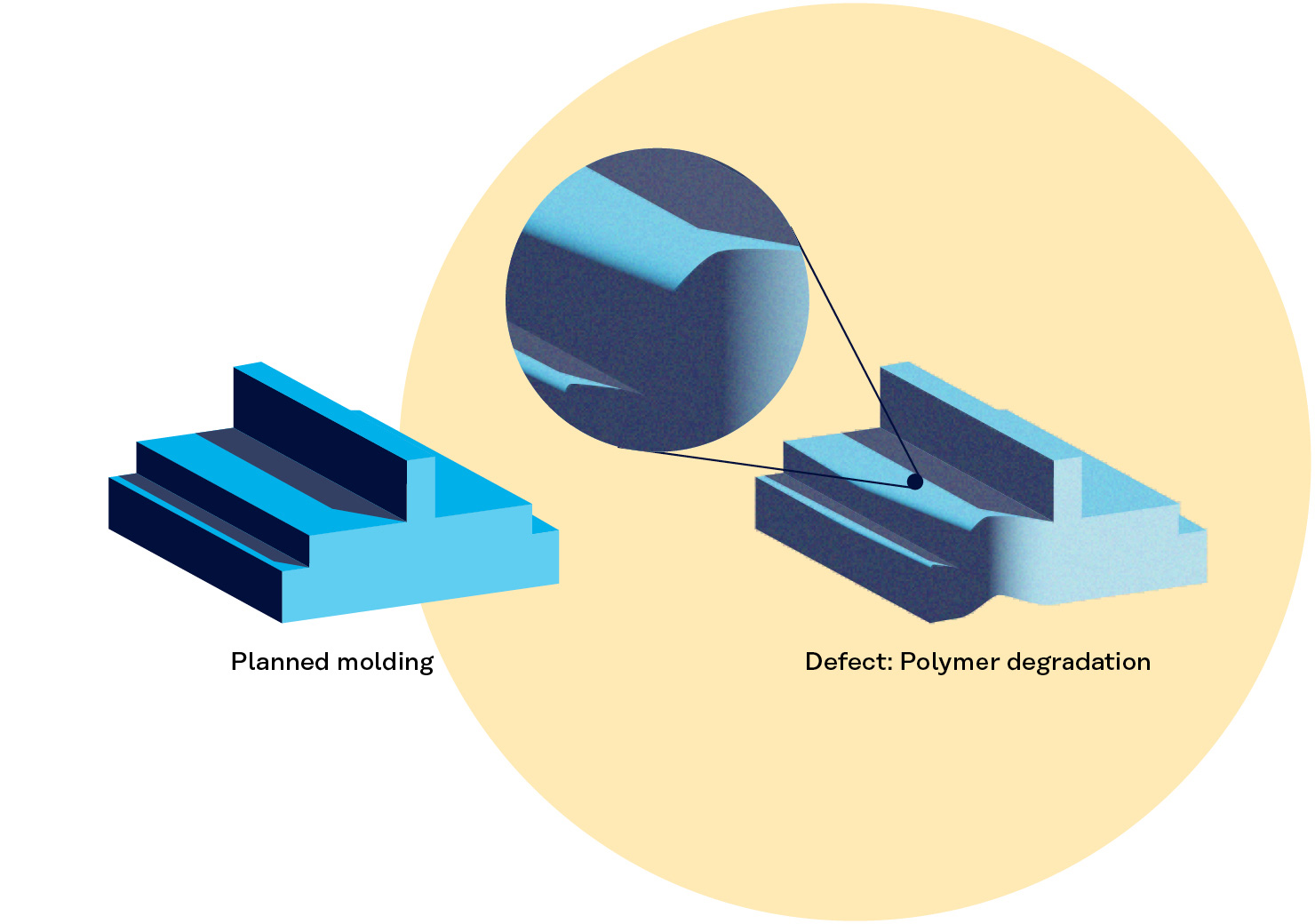

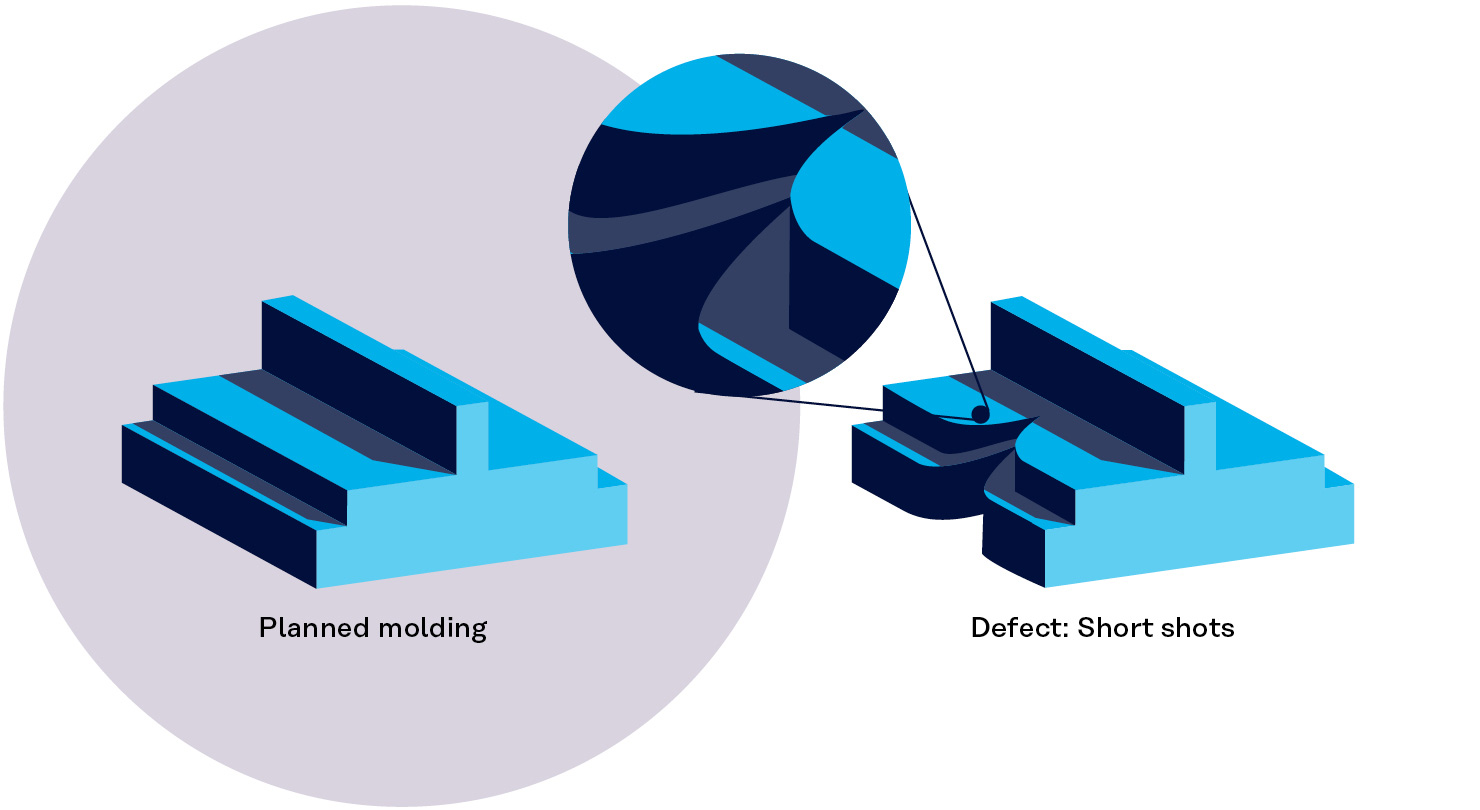

Material-dependent defects

Polymer degradation is an example for a material-dependent defect. If the material has gone through hydrolysis, oxidation or another cause of polymer degradation, the molded parts will show it in the form of cracks, discoloration or similar defects.

Another material-dependent defect: Short shots. If there is not enough material in the injection molding machine, the molded part will have unfilled sections. Alternatively, this can also be causes by insufficient flow rate.

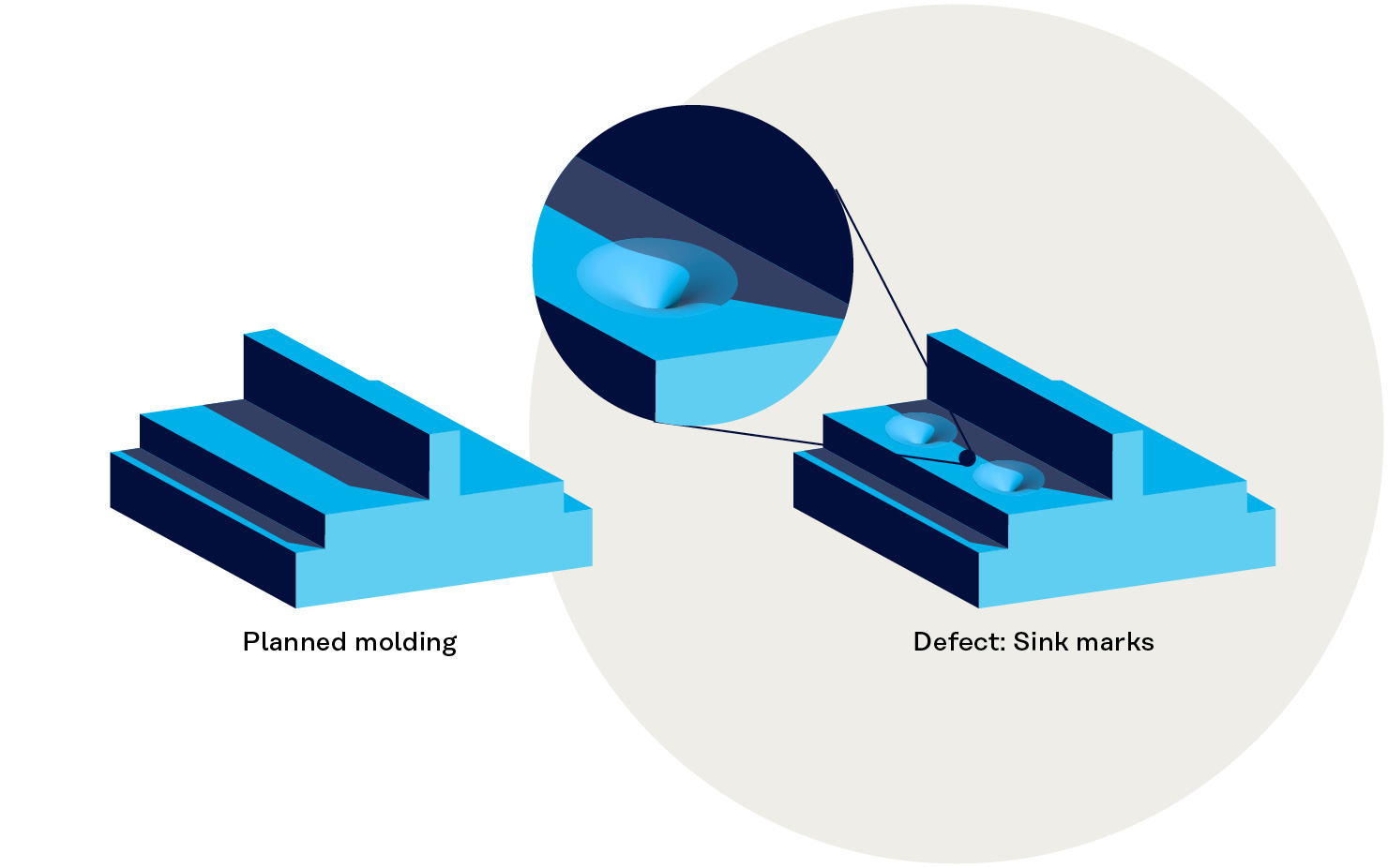

Equipment and material-dependent defects

As equipment and material affect each other, it is common to have defects caused by both. For example, sink marks can be an equipment-dependent defect if the cooling rate is too high. This can make the surface of the part solidify before the material in the center has time to flow in place. Alternatively, they can be a material-related defect as some materials, such as filled or reinforced resins, have a higher tendency to shrink and display sink marks.

Examples of equipment-related defects that cause ejector marks are poor mold design (especially regarding gates), poor ejector pin design or inadequate mold maintenance. On the other hand, material-related defects such as brittleness or low impact resistance could also lead to ejector marks.

Again, this list of defects and their reasons is incomplete. We are merely presenting some examples.

Good to know

Kuraray’s raw materials are excellent additives that can help reduce molded part defects in injection molding. They can improve important material properties, such as flow and shrinkage.

Injection molding materials

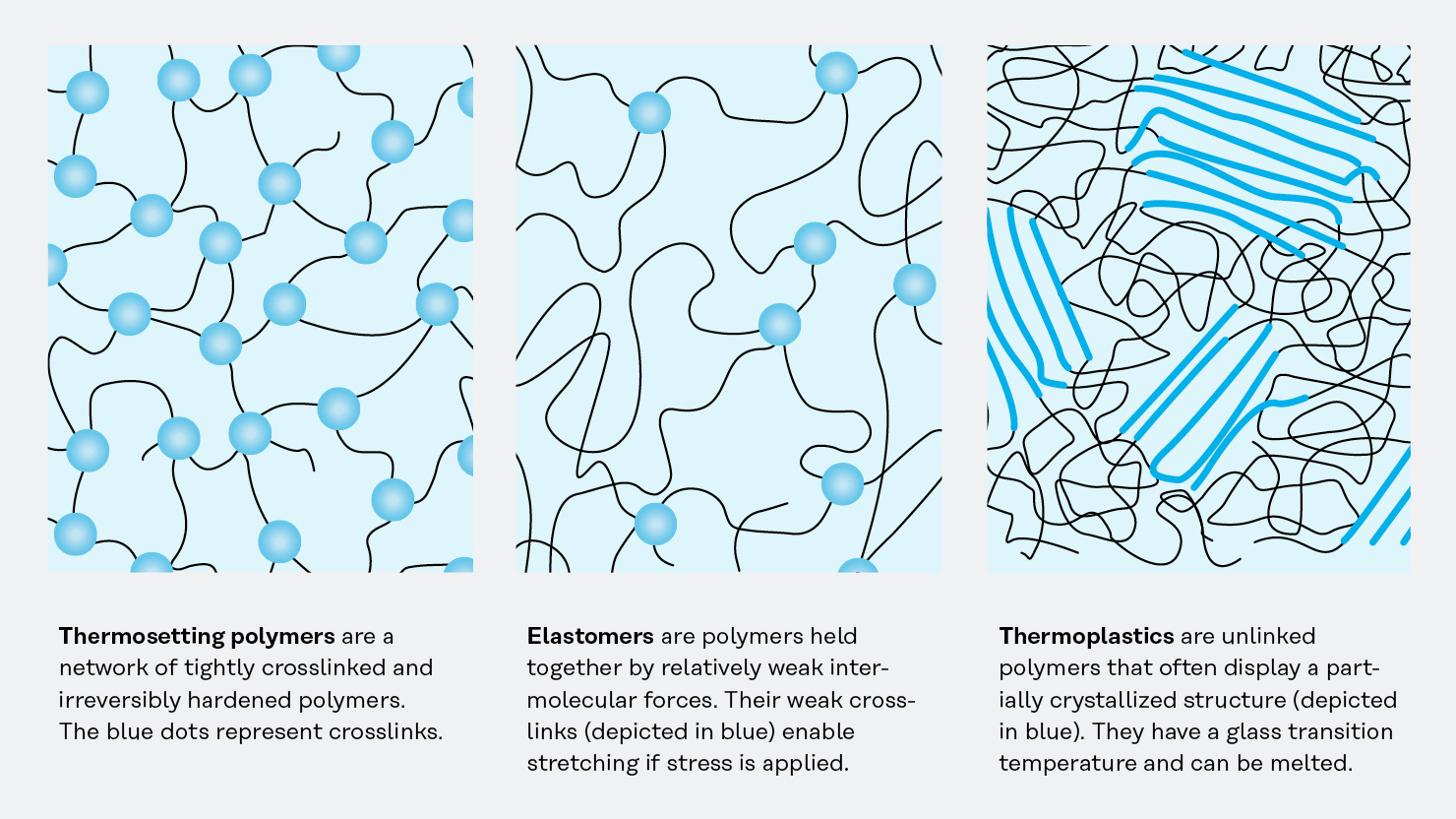

All thermoplastics, as well as some thermosets and elastomers are suitable materials for injection molding.

The most frequently used thermoplastics in injection molding worldwide are polypropylene (PP), acrylonitrile butadiene styrene (ABS), polyethylene (PE) and polystyrene (PS).

As “soft” materials for 2K and 3K injection molding, thermoplastic elastomers (TPEs) are most commonly processed.

It is rather uncommon for thermosets to be used in injection molding. This is because of their cross-linking density and their inability to be re-melted and reshaped. However, some thermosets are used as additives in certain applications such as improving the properties of thermoplastic parts.

The materials are usually available as small pellets or as a fine powder. In some cases, they are liquid. By adding various additives, the properties of the molded parts or the processability of the material can be improved. Examples of additives include colorants for color or glass fiber for increased stiffness. However, there are also more advanced additives, such as the specialty elastomers from Kuraray.

Each material requires different parameters during processing to get the desired molded parts. These include injection temperature and pressure, mold and ejection temperature as well as cycle time. Depending on how these parameters are set, the appearance, dimensions and mechanical properties of the molded parts change considerably. In addition to the appropriate technology, a great deal of experience is required.

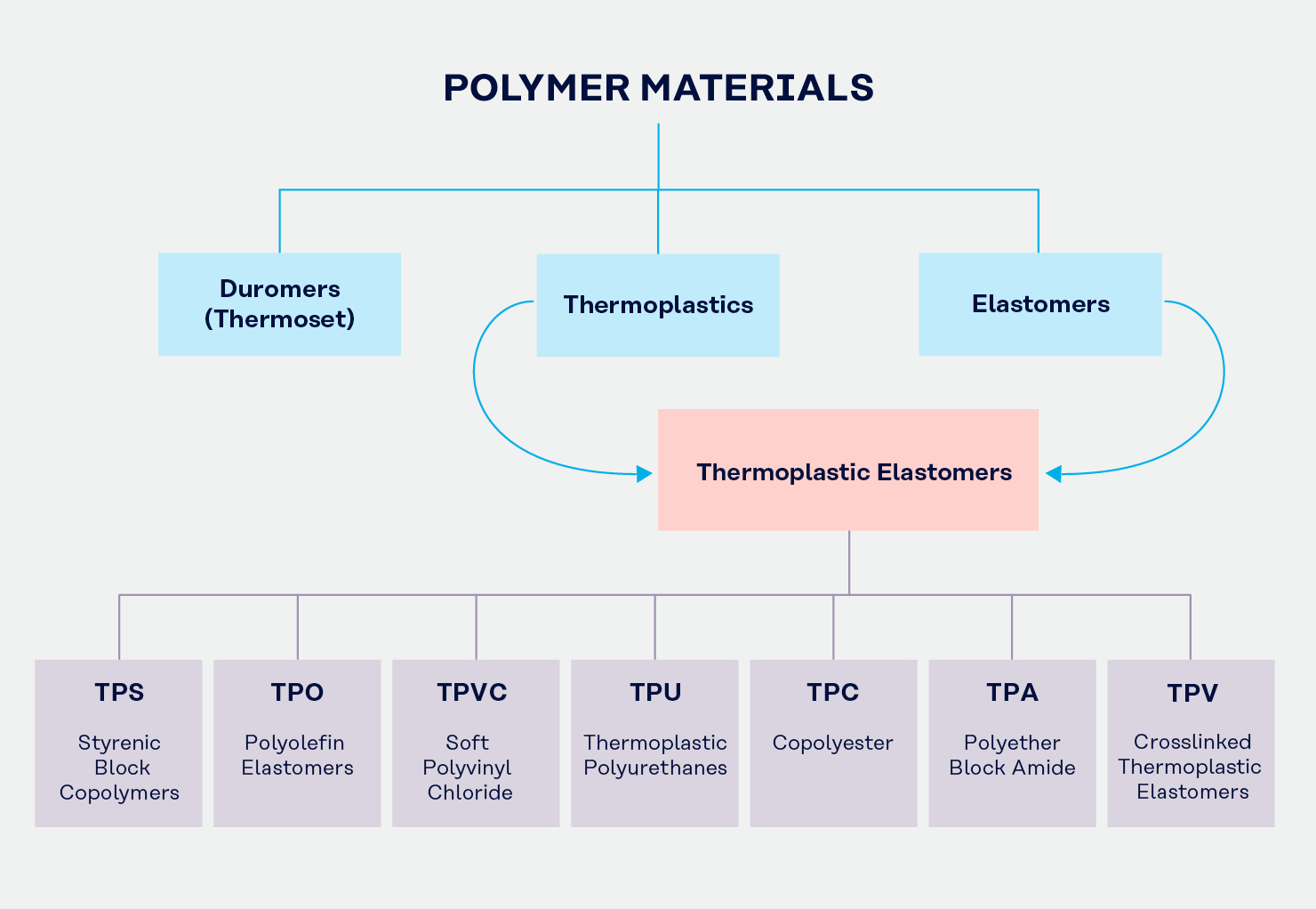

Thermoplastic elastomers

Thermoplastic elastomers (TPEs) are materials with a rubber-like elasticity and the processability of thermoplastics. In other words, they can be stretched like a rubber band and melted and molded into a wide variety of shapes and sizes. After cooling, they keep their elasticity. If needed, they can be re-melted and re-molded again later on, which also implies less material waste in processing.

The processability of TPEs makes them an excellent material for injection molding. Unlike rubber, they do not require vulcanization, which is a time-intensive rubber processing method. Due to their diverse applications, they are a well-suited material for many industries and purposes.

To learn more about the material properties of different kinds of TPEs, please refer to the following table.

| Properties/Materials | TPS | TPO | TPVC | TPU | TPC | TPA |

| Shore Hardness | 30A 〜 70A | 60A 〜 95A | 40A 〜 70A | 80A 〜 80D | 90A 〜 70D | 40D 〜 65D |

| Tensile strength (MPa) | 9.8 〜 34.3 | 2.9 〜 18.6 | 9.8 〜 19.6 | 29.4 〜 49 | 25.5 〜 39.2 | 11.8 〜 34.3 |

| Elongation (%) | 500 〜 1,200 | 200 〜 600 | 400 〜 500 | 300 〜 800 | 350 〜 450 | 200 〜 400 |

| Rebound resilience (%) | 45 〜 75 | 40 〜 60 | 30 〜 70 | 30 〜 70 | 60 〜 70 | 60 〜 70 |

| Density (g/cm³) | 0.91 〜 0.95 | 0.88 | 1.2 〜 1.3 | 1.1 〜 1.25 | 1.17 〜 1.25 | 1.01 |

| Abrasion resistance | Fair | Poor | Fair | Excellent | Fair | Good |

| Bending resistance at room temperature | Good | Fair | Good | Good | Excellent | Excellent |

| Heat resistance | 〜 80°C | 〜 120°C | 〜 100°C | 〜 100°C | 〜 140°C | 〜 100°C |

| Oil resistance | Poor | Fair | Good | Excellent | Excellent | Excellent |

| Weather resistance | Poor - good | Good | Fair - good | Fair - good | Fair | Good |

| Brittleness temperature | < -70°C | < -70°C | -50°C 〜 -30°C | < -70°C | < -70°C | < -70°C |

| Applications | Footwear, resin blends, adhesives, asphalt modification | Automotive hoses / tubes, consumer goods | Automotive, electric wires / cables, civil engineering / construction | Footwear, industrial goods, consumer goods, medical goods | Automobiles, electronics, industrial goods | Sporting goods, industrial goods |

Thermoplastic elastomers from Kuraray

Kuraray offers high-performance plastics for injection molding to achieve better material properties. Whether for complete parts or as flexible PVC/rubber replacements, the key properties of these plastics add real value to your products and help make your processes more efficient.

Kuraray’s materials facilitate the efficient production of plastic components on a large scale. For 2K injection molding, Kuraray offers high-performance TPEs that can serve as soft functional components.

SEPTON™

SEPTON™ is a series of styrenic thermoplastic elastomers developed by Kuraray. The Hydrogenated Styrenic Block Copolymers (HSBCs) consist of styrene-based hard blocks and a hydrogenated diene soft block. HSBCs exhibit rubber-like elasticity since the hard block acts as a crosslinking point below the glass transition temperature of polystyrene and the soft block provides elasticity. Hydrogenation generates excellent heat and weather resistance.

Benefits

By adding SEPTON™ and plasticizer to polyolefins, good injection moldability and flexible molded parts can be obtained.

By using SEEPS grades of SEPTON™, emboss transferability is improved, and adhesion in insert molding is also improved.

SEPTON™ BIO-series

With SEPTON™ BIO-series, Kuraray offers a unique hydrogenated styrene farnesene block copolymer (HSFC) – which makes Kuraray the first and only manufacturer of bio-based HSBC materials on the market. SEPTON™ BIO-series thermoplastic elastomer represents a new solution for manufacturers that enables new compounds and end-uses with a high bio-based content to expand existing market areas and open up new ones.

For additional benefits, please refer back to the previous section about SEPTON™ or contact sales.

HYBRAR™

HYBRAR™ is a truly unique triblock copolymer consisting of polystyrene end blocks and a vinyl bonded rich poly-diene mid-block. Due to its peak tan delta near room temperature, HYBRAR™ exhibits high vibration damping and shock absorption properties – even without integrated plasticizer. These TPEs are available as durable hydrogenated and non-hydrogenated grades.

Benefits

By adding a small amount of HYBRAR™ to polypropylene, the crystallinity is lowered and the transparency can be improved.

Liquid rubbers

Liquid rubbers are widely used as “reactive plasticizers” or modifiers in rubber and plastic and can also be used in injection molding. Liquid rubbers are liquid polymers with lower molecular weight and they have the same chemical structure as a solid rubber.

Liquid rubbers are in a liquid state at room temperature, while exhibiting rubber-like properties after chain elongation and cross-linking. Examples of liquid rubbers include:

- liquid diene rubbers such as liquid butadiene rubbers, liquid isoprene rubbers and liquid styrene-butadiene rubbers

- liquid silicon rubbers

- liquid olefin rubbers

- liquid urethane rubbers

KURARAY LIQUID RUBBER

KURARAY LIQUID RUBBER is a cross-linkable liquid rubber. It comprises liquid butadiene rubber (L-BR), liquid isoprene rubber (L-IR) and liquid styrene-butadiene rubber (L-SBR). The liquid rubbers are colorless, transparent, almost completely odorless and have low VOC values. The polymers of butadiene, isoprene and styrene have a low molecular weight which is between solid rubber and plasticizer.

KURARAY LIQUID RUBBER products are designed as “reactive plasticizers”, meaning: In the time-consuming and labor-intensive rubber mixing process, they help reduce Mooney viscosity and facilitate the mixing process. This results in increased flowability of the compound as well as reduced time requirements and lower processing costs.

In addition, KURARAY LIQUID RUBBER products are co-vulcanizable with the base rubber to prevent migration. The significantly reduced migration massively improves the shelf life and durability of the products.

KURARAY LIQUID RUBBER is well-suited for the injection molding of rubber compounds.

Benefits

KURARAY LIQUID RUBBER can enhance the injection molding process of rubber compounds in several ways:

- Flowability: As a processing aid, it reduces melt viscosity and makes rubber compounds more fluid and easier to inject into the mold cavity. This allows the material to reach tight corners of the mold cavity and visibly improve the surface, which results in a more accurate replication of the mold.

- Reduced energy consumption: Better flowability of the compound increases the efficiency of the mixing and molding process significantly. KURARAY LIQUID RUBBER can help to reduce the molding temperature, which lowers the energy consumption.

- Properties and performance: KURARAY LIQUID RUBBER can increase the properties and performance of the final rubber products, namely abrasion resistance and flexibility at low temperatures. In addition, KURARAY LIQUID RUBBER can reduce migration and improve the shelf life and durability of the final rubber products, compared to normal plasticizers.

Good to know

The optimal amount of KURARAY LIQUID RUBBER to be added to the rubber compound depends on various factors. Contact us to learn more about how you can achieve better results in injection molding with KURARAY LIQUID RUBBER!

Liquid farnesene rubber

Do you value sustainability?

Liquid farnese rubber (LFR) is based on natural and renewable raw materials: It contains a polymerized form of β-farnesene, a renewable monomer. Through established fermentation processes, proprietary yeast strains convert sugar sources such as sugarcane into β-farnesene.

Liquid farnesene rubber functions as a reactive plasticizer with a higher molecular weight than standard plasticizer. Liquid farnesene rubber is co-vulcanizable and reduces migration significantly which improves the durability of rubber compounds.

Would you like to learn more about our products and their excellent processing capabilities? Then please contact your Kuraray representative.

Other materials

In addition to plastics, a variety of other materials can be used for injection molding such as metals. However, the injection molding process for metals is commonly referred to as die casting.

Injection molding: Advantages

The main advantage of injection molding is the production of parts in large quantities. The range of applications extends from small batches of several hundred pieces to mass production with quantities of several million components.

Once the initial investment has been amortized, the unit price is extremely low with this manufacturing process. As the number of units increases, the unit cost can drop significantly. This makes this process highly productive.

Other advantages of injection molding include high repeatability and tolerances, a wide range of materials, low scrap rates, and an attractive visual appearance of the molded parts.

Disadvantages

A major disadvantage of injection molding is the high startup costs associated with building the molds.

It can also be expensive if changes need to be made to the design of the molds to adapt the process, or if design errors occur. Even small errors can result in large costs here.

Other disadvantages include longer start-up times and possible limitations with larger molds.

Applications

Injection molding is used in a variety of industries including consumer products (toothbrushes), furniture (chairs), automotive (dashboards), electronics (power tool housings), toys (plastic building blocks), healthcare (syringes), packaging (screw caps) and many more.

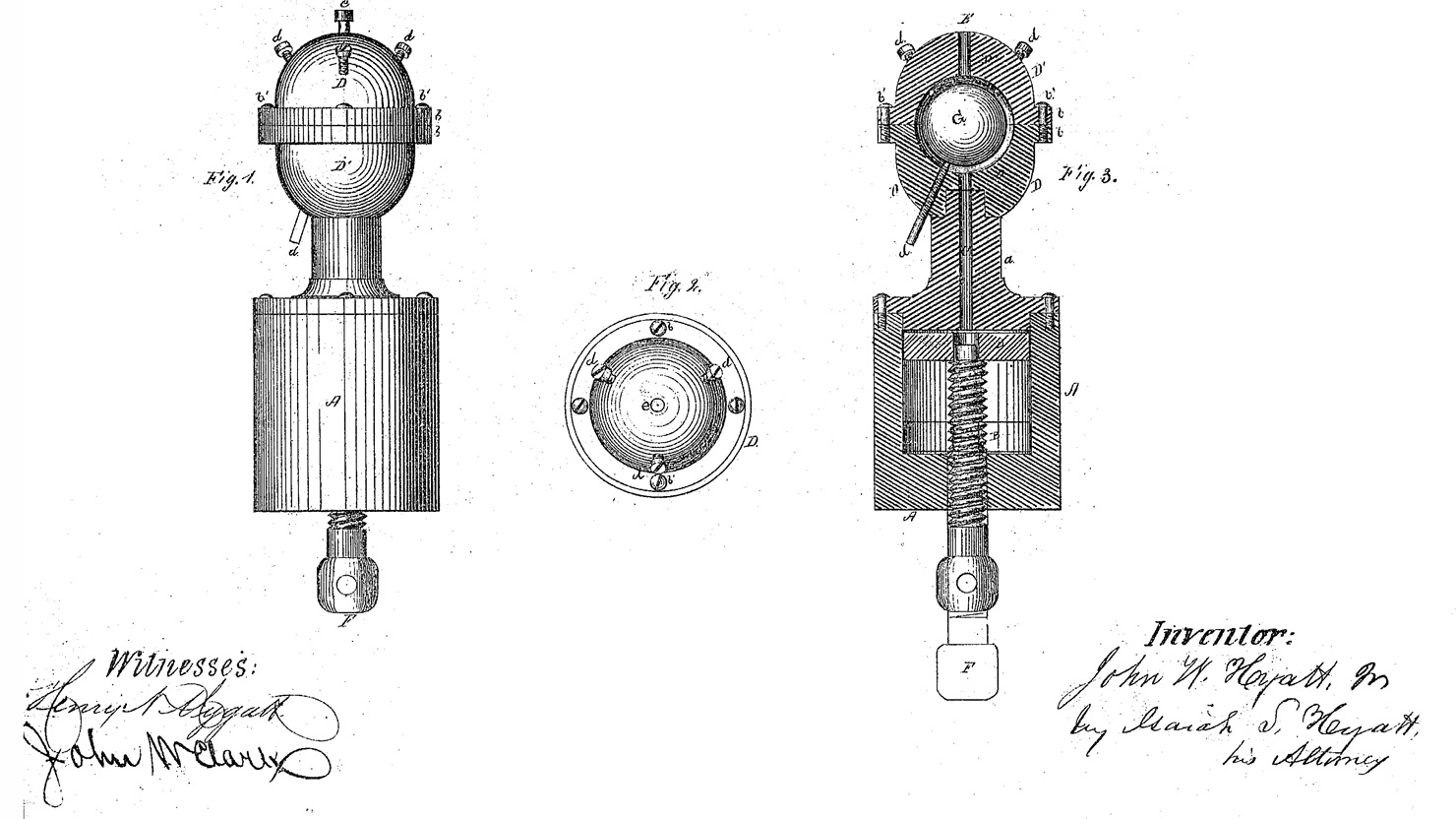

History

The inventor of injection molding is the American John Wesley Hyatt. He patented the first injection molding machine together with his brother Isaiah in 1871. At that time, it was still a fairly simple machine in which plastic was injected through a heated cylinder into a mold with the aid of a piston. It was used to manufacture products such as buttons, combs and billiard balls.

In 1903, German chemists Arthur Eichengrün and Theodore Becker invented the first soluble forms of cellulose acetate which could be easily injection molded in powder form. It was also Eichengrün who developed the first injection molding press in 1919 and patented the injection molding of plasticized cellulose acetate two decades later.

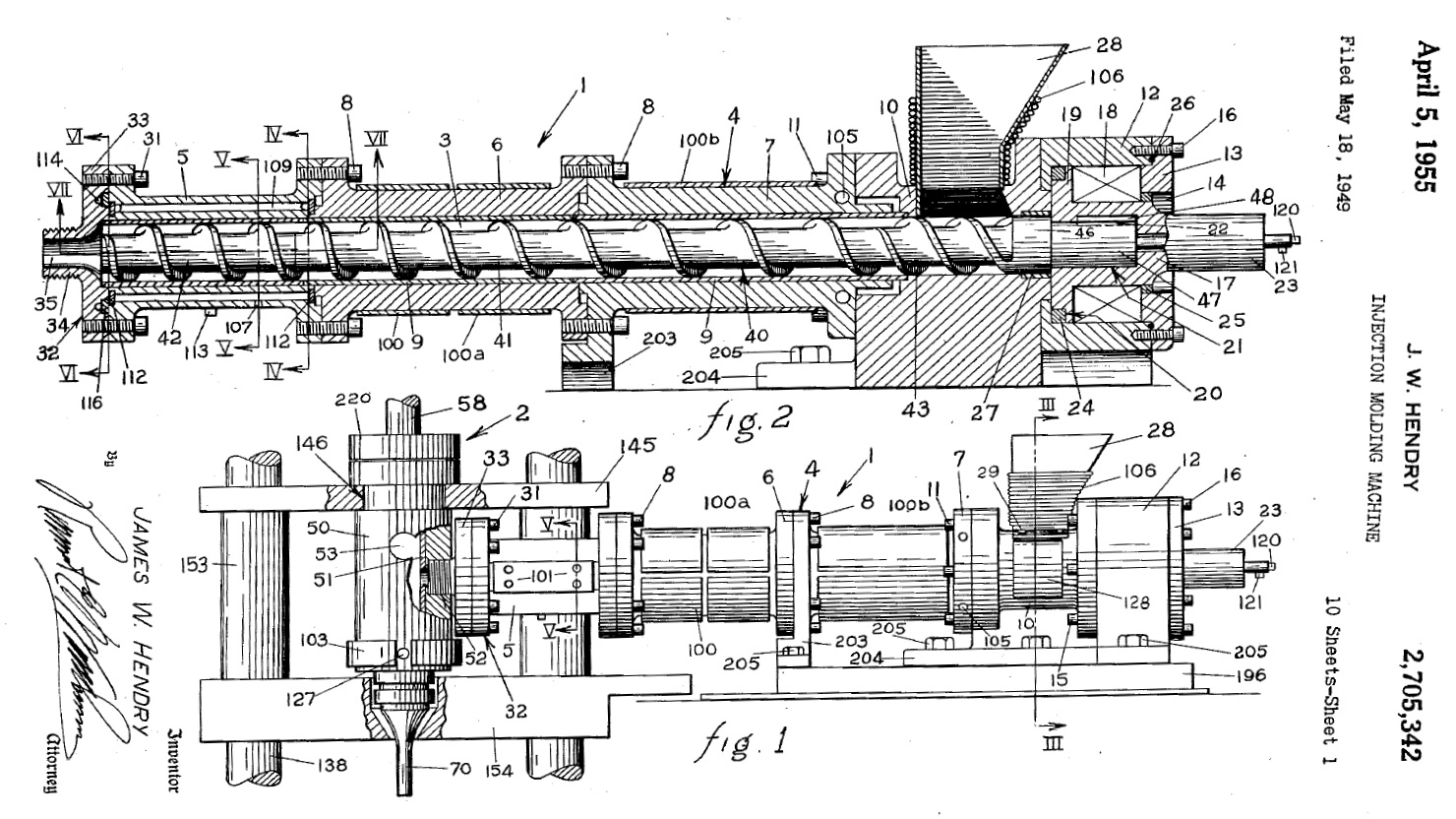

During the Second World War, the industry expanded strongly due to the high demand for inexpensive mass products. In 1946, the US American James Watson Hendry made a groundbreaking development with the first screw injection molding machine. It not only allowed much more precise control of the injection speed and quality of the molded parts, but also allowed the material to be mixed before injection.

Another Hendry development from the 1970s, the gas-assisted injection molding process, enabled the production of complex, hollow articles and greatly improved the design flexibility, strength and surface finish of injection molded parts.

Today, injection molding is a global market with annual sales of hundreds of billions of dollars. Worldwide, around 55 million tons of plastics are processed with it each year.

Standards & certifications

There are a number of certifications that can confirm the qualification of your injection molding service provider. Of particular importance is ISO 9001 certification.

The Society of the Plastics Industry (SPI) has additionally defined standards for the optical quality of plastics for the US plastics industry. The standards define the surface qualities of injection molded plastic parts distinguishing between twelve different surface qualities in four categories.

Costs

Injection molding offers significant advantages for the production of molded parts in high volumes. However, anyone opting for this process must also be aware of the start-up costs. The initial investment can be very high. In addition to the injection molding machine, the costs for the molds are particularly significant and can sometimes run into the millions.

This may be of interest to you: Kuraray supports you in the development of compounds for faster cycle times and optimized production for the highest possible profitability of the injection molding process.

You have a clear idea of the product you want to produce, but you are not sure about the recipe and composition of the materials? Then contact your Kuraray representative. We will be happy to help you with our process and material expertise and support you in the organization of your supply chain, if required.

Contact for business

We are looking forward to your inquiry!

Contact