SEPTON™ V-series: The vulcanizable SBC

SEPTON™ is a series of hydrogenated styrenic thermoplastic elastomers (HSBCs). It is used in a great number of TPE compounds and can be processed in a wide variety of forms. Specific grades are certified and used in consumer goods, medical, mobility and oil modification applications. These styrenic TPEs cover a broad range of applications including compounds, polymer modification, adhesives, flexible PVC substitutes and vibration damping products.

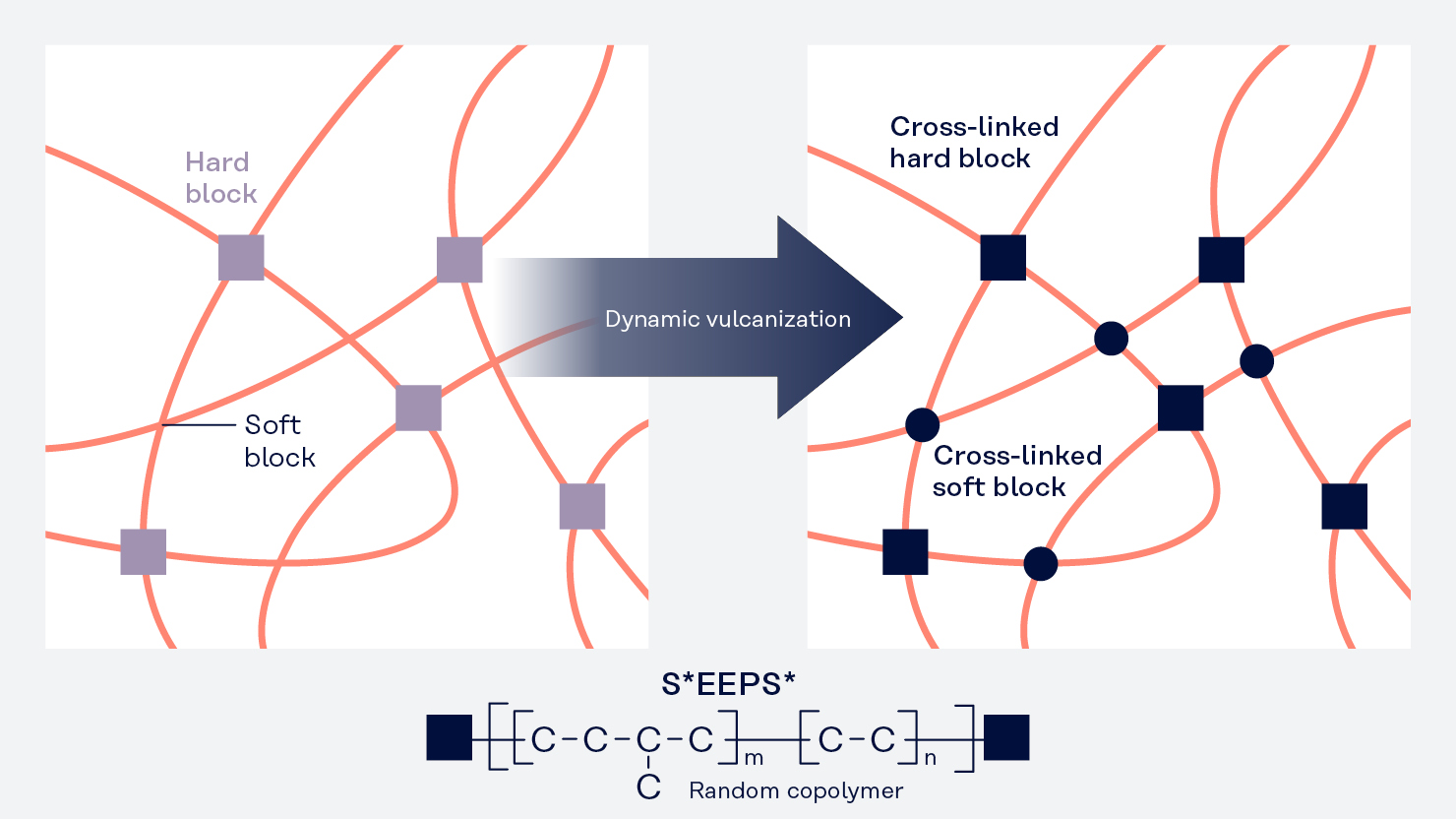

The HSBCs consist of styrene-based hard blocks and a hydrogenated diene soft block. HSBCs exhibit rubber-like elasticity since the hard block acts as a crosslinking point below the glass transition temperature of polystyrene and the soft block provides elasticity. Hydrogenation generates excellent heat and weather resistance.

However, the market demands and requires thermoplastic elastomers, that are suitable for particularly harsh operating conditions, such as extremely high temperatures. For some applications, the oil resistance of current TPEs is not sufficient.

To further improve the temperature and oil resistance of thermoplastic elastomers (TPEs), Kuraray has developed SEPTON™ V-series, an innovative styrene block copolymer (SBC). The ‘V’ stands for ‘vulcanizable’ and refers to the cross-linkable hard blocks of SEPTON™ V-series. Once the hard blocks are cross-linked, the material gains better performance characteristics under extreme heat than a compound based on conventional styrenic block copolymers.

In SEPTON™ V-series, the structure of the hard blocks of the styrene elastomer has been modified to meet these special requirements. The block copolymer has vulcanizable hard blocks and soft blocks. Crosslinked SEPTON™ V-series exhibits excellent heat resistance, long term compression set and oil resistance, while keeping its elastic properties and satisfying low temperature properties, caused by the vulcanized hard blocks.

Features and Benefits

- Suitable for dynamic vulcanization

- Heat resistance

- Long-term stable compression set

- Chemical and oil resistance

- Higher elongation at break

- Better processability than EPDM

Applications

- Industrial & construction

- Mobility

The mechanical properties of rubber can only be achieved through vulcanization. The dynamic vulcanization of SEPTON™ V-series can replace the expensive and time-consuming vulcanization step that would be necessary in regular rubber processing. This makes SEPTON™ V-series an interesting alternative for EPDM and TPV, with the benefit of having the good processability of a TPE.

Kuraray’s competence in catering to the needs of compounding applications allows both the hard blocks and soft blocks to dynamically crosslink while SEPTON™ V-series is on the extrusion line. For clients interested in dynamic vulcanization, Kuraray readily provides its expertise.

Dynamic vulcanization creates compounds with higher oil and heat resistance (especially with low compression set values at elevated temperatures). These compounds are suitable for application in markets where vulcanized rubber is used, such as automotive sealing and structural materials (e.g. underhood), where conventional TPEs can melt. Vulcanized SEPTON™ V-series compounds have low compression set values after 1,000 hours and more.

Contact