What are oil additives?

Oil additives are compounds added to oils to improve their lubrication performance. They give the base oil key properties such as reduced friction, controlled viscosity, longer lifespan, improved engine efficiency, and cleaner operation. Oil additives are an essential component of modern engine oils, gear oils, and even hydraulic fluids—without them, these products would be unable to protect and lubricate modern machinery.

Types of oil additives by purpose

Oil additives can provide many benefits when added to a base oil, including improved viscosity, longevity, lubrication, and efficiency. Most oil modifications include multiple oil additives to offset the negatives of the base oil and improve the quality of the product.

Oil additives for viscosity

To be an effective lubricant, oil must be able to flow as needed to reach all vulnerable parts. Since machines like engines may operate at a wide range of temperatures, from starting on cold mornings to running at high heat, the oil must retain the correct degree of viscosity in a variety of conditions. Oils accomplish this with a variety of additives according to the needs of their applications.

Viscosity index improvers

Oils often include viscosity index improvers, complex polymers that close the gap between an oil’s viscosity at high and low temperatures. Oils decrease in viscosity as temperature increases, making them thin, runny, and less effective as lubricants. These additives improve the thickening efficiency of a formulation as temperatures increase, allowing the product to maintain lubricating efficiency and oil pressure.

Pour point depressants

Pour point depressants are added to oils with higher base viscosities that may lose their ability to flow in the cold if the temperature drops below their pour point. To keep the oil’s flowability at lower temperatures, some formulations include pour point depressants that lower their viscosity.

Oil additives for chemical breakdown control

These additives work to protect both the oil and the machinery from the long-term effects of chemical processes like oxidation and corrosion.

Antioxidants

Usually phenols or amines, these compounds are added to prevent the oxidation of the base oil, which decreases its lubricity over time and increases wear on the machinery. To slow this degradation and increase the lifespan of the oil, antioxidants (sometimes known as oxidation inhibitor additives) are added to limit the oxidation process.

Corrosion inhibitors

These compounds protect lubricated machines that are exposed to air and may corrode over time, like engines. By forming a lasting, protective layer as the oil moves, corrosion inhibitors prevent oxygen from oxidizing the metal of the engine to form rust, increasing its lifespan.

Good to know

Oxidation occurs as the oxygen in air undergoes a chemical reaction with a substance. In oils, oxygen reacts with oil molecules to change their structure, degrading their quality over time. Antioxidants are added to oils to slow this process.

Corrosion is the deterioration of a metal through electrochemical reactions with its surroundings. While oxidation is one way a metal can corrode, it may also undergo corrosion from electrochemical interactions with other gases or liquids. Oils prevent this by coating the metal, preventing contact with corroding agents.

Oil additives for lubricity

Although the base oil provides the foundation for a product’s lubricity, oil additives are often necessary to achieve the lubricating power that modern machinery requires. These additives further reduce friction and ensure that the oil can lubricate machinery as soon as it begins to operate.

Friction modifiers

These compounds, which include organic friction modifiers, organo-molybdenum compounds, and even dispersed nanoparticles, are added to reduce wear and tear on machinery and improve the efficiency of motors and engines. They improve the lubricity of the base oil, making it a more effective formulation for protection and engine efficiency.

Antiwear agents

Antiwear additives include compounds like zinc dialkyldithiophosphate, zinc dithiophosphate, and tricresyl phosphate. They form a protective film over metal parts, keeping them from directly contacting each other, reducing wear when machinery moves before oil can spread, and improving longevity and efficiency.

Oil additives for contaminant control

The machines that oils lubricate operate under a variety of conditions that expose them to contaminants. Oil additives neutralize those contaminants to maintain efficiency and prevent blockages. Dispersants prevent the machinery from contaminating the oil, while detergents prevent the oil from contaminating the machinery.

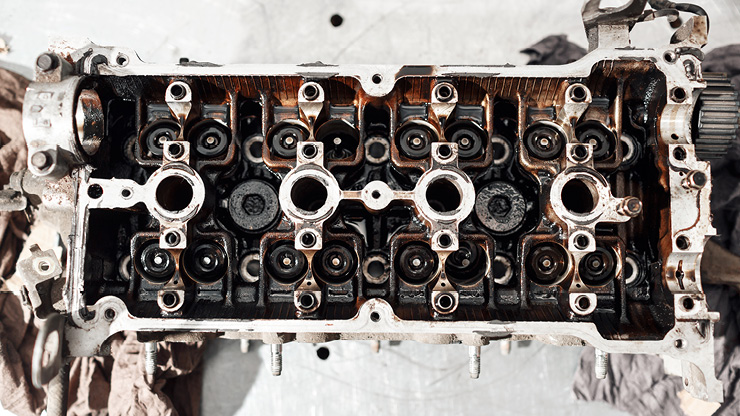

Dispersants

As machinery undergoes wear over time, small metal particles and combustion byproducts contaminate the engine and its oil. These particles can be controlled through the addition of dispersants, which are typically surfactants. These compounds prevent blockages and maintain lubricity by keeping contaminant particles separated and suspended in the oil. In an engine, this also allows these contaminants to be effectively removed by the oil filter.

Detergents

Detergent additives, which are usually magnesium sulfonates, counteract any acids that form and remove impurities in the oil to prevent engine deposits. These blockages put wear and tear on machinery and decrease engine performance. Detergents neutralize acids and break down these impurities to keep machinery clean as oil is added and used.

Anti-foam agents

Anti-foam agents, also known as defoamers, range from insoluble oils to alcohols and glycols. When air bubbles form in oil or detergents are added, a foam can form that decreases lubrication and increases corrosion. Anti-foam agents prevent this by acting at the surface of the oil to rupture any air bubbles that form.

Advantages of oil additives

Although the petroleum and synthetic oils chosen as bases for oil formulations already have desirable characteristics, none are directly usable in most practical applications. Oil modification through oil additives provides those necessary properties not found in base oils.

Additives offer the ability to control lubricity, the most important quality of any oil. To develop formulations with the lubricating power necessary for parts under significant, sustained wear, products use additives like friction modifiers and antiwear agents to protect machinery and increase efficiency.

The oil’s viscosity can also be controlled with additives. This key property dictates how the oil functions across various temperatures. Additives allow the base oil’s viscosity to be adjusted up or down as needed at room temperature, decreased at lower temperatures, and increased at higher temperatures to ensure consistent lubrication in all operating conditions. Without them, no base oil would remain consistently effective at the temperatures required by modern engines.

Many additive compounds also improve the longevity of both the oil and the machinery, lowering costs. Friction modifiers and antiwear agents accomplish this by reducing wear and tear on parts through superior lubrication. Detergents, anti-foam agents, and corrosion inhibitors work to reduce frequency of oil changes by breaking down contaminants, maintaining lubrication, and preventing corrosion of machinery. Dispersants and antioxidants increase the lifespan of the oil by suspending contaminant particles and inhibiting the degradation of the base oil.

In addition to their operational benefits, oil additives are also drivers of sustainability. By increasing the lifespan of base oils and engines, additives decrease the amount of petroleum and synthetic motor oils that need to be manufactured, reducing fossil fuel consumption, energy consumption, and pollution. Oil additives also decrease wear and tear on engines and make them more efficient, reducing air pollution and limiting the need for new vehicles and parts.

Oil additives may also be flexible and multipurpose, adding several desirable qualities to a formulation at once. Zinc dialkyldithiophosphate, a common additive in engine oils, functions simultaneously as an antioxidant, corrosion inhibitor, and antiwear additive.

Looking for a set of viscosity index improvers for oil modification from engines to hydraulics?

Get in touch with our team using the form below to learn more about SEPTON™ and KURARAY LIQUID RUBBER, flexible polymers with low addition rates that improve thickening efficiency, shear stability and low temperature property.

Disadvantages of oil additives

Although additives are key to all oil formulations, they come at an increased cost. Cost-effective products should consider additives that are effective in lower concentrations or that accomplish more than one goal.

Oil additives may also have incompatibilities with a base oil or with other additives in the oil. To develop a stable, effective product, it is always important to ensure that an additive will be chemically compatible with a base oil and any other additives in the formulation.

Interim summary: Are oil additives worth it?

Oil additives are an essential component of any functional oil that provide crucial qualities from lubricity to longevity. Although additives increase the cost and complexity of a product, an oil formulation simply isn’t effective—or competitive—without them.

Applications: Oils to modify

Oil additives are most often discussed as components of engine oil, but they are also a critical part of a variety of machine oils. Wherever consistent lubrication and flexible physical and thermal properties are required, oil modification is the solution.

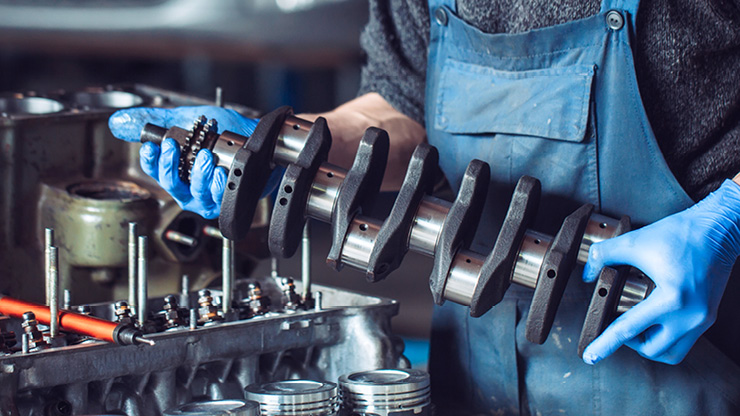

Engine oil

Engine oils, whether petroleum or synthetic, must be adapted to an extremely wide variety of engine types, engine fuels, operating temperatures, applications, volumes, service lifespans, and more. This flexibility is achieved through oil additives that adjust qualities ranging from viscosity and lubricity to lifespan and protecting power.

Gear oil

Although an engine requires the most oil and the most frequent changes, quality lubricant is also critical to the function of gearboxes, bearings, and transmissions. In these applications where lubricant may go unchanged for long periods of time, additives for viscosity, lubricity, seal conditioning, and longevity are especially important.

Hydraulic fluid

Hydraulic fluids are often based on mineral oils, which benefit from many of the same properties provided by oil additives used in engine and gear oils. Hydraulic fluids must be effective sealants, lubricants, and power transmitters. To provide these qualities, fluids based on mineral oils rely on additives that improve viscosity, corrosion and oxidation control, shear stability, low-temperature fluidity, and foaming.

How to choose the right oil additives

There are many important considerations when selecting oil additives, but the questions below cover some of the most common factors.

- Base oil: What are the physical properties of the base oil? Does its viscosity need to be raised or lowered? How stable is it? Will the additive be compatible with it?

- Other existing additives: What additives are key to the formulation? Which additives are compatible with each other, and which are not?

- Service environment: What kind of machinery will the oil be used for? What operating conditions or contaminants will it be exposed to? Will foaming, corrosion, or oxidation be an issue?

- Temperature range: What temperature range will the oil need to be effective in? If lower temperatures are required, does it need a pour point depressant? If higher temperatures are required, does it need a viscosity index improver?

- Service life: How long will the oil be in use before it is changed? Will it be fully changed or replenished?

- Cost: How expensive is the additive? Does it provide an improvement in performance equal to its cost, and if not, can a less expensive or more potent additive be used instead?

- Availability and compliance: Can the additive be reliably obtained and transported? Does it meet regulatory requirements in the application or industry in which the oil will be used?

Consider these factors alongside important properties like viscosity, lubricity, and longevity.

Oil additive materials from Kuraray

One of the most critical physical properties of an oil in any application is its viscosity. To support your oil modifications, Kuraray offers multiple products as viscosity modifiers that improve shear stability and thickening efficiency and cover applications ranging from engine oil to hydraulic fluid.

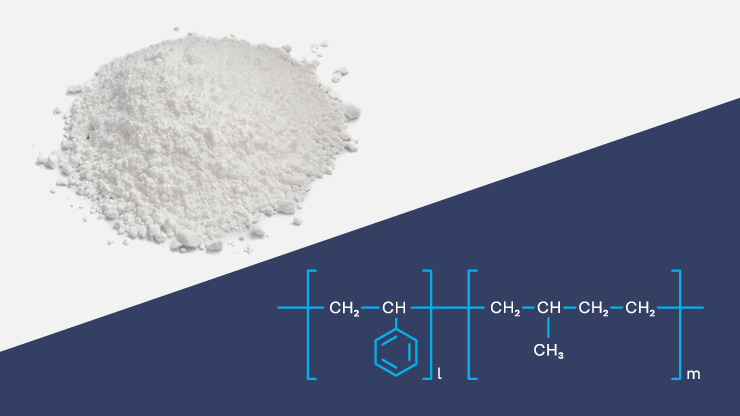

SEPTON™, the versatile TPE

SEPTON™ 1020 is a heat-resistant thermoplastic elastomer with SEP structure from the SEPTON™ product line. It features good viscosity index, shear stability, low temperature property, excellent compatibility, and is ideal for use as a viscosity modifier. SEPTON™ 1020 operates at both low and high temperatures, making it a valuable additive especially in engine oils,—and even as a thickener in lithium grease. To help decrease the cost of your formulation, this flexible additive is also effective at a lower addition rate than other comparable compounds. If you need a versatile, cost-effective viscosity modifier for a range of applications, reach out to our experts at Kuraray to learn more about SEPTON™.

KURARAY LIQUID RUBBER

KURARAY LIQUID RUBBER is a viscosity modifier that improves thickening efficiency and shear stability. Although its low heat resistance limits its use in engine oil applications, KURARAY LIQUID RUBBER is an excellent choice for use in gear oil and hydraulic fluid. Like SEPTON™, it is an effective viscosity modifier at a lower addition rate than comparable compounds, making it a cost-effective option. For low-cost, low-temperature transmission oil, gear oil, and hydraulic fluid applications, get in touch with our team to learn more about KURARAY LIQUID RUBBER.

Conclusion

Oil additives allow for essential modifications to oil formulations that improve lubrication, increase longevity, reduce emissions, protect machinery, and adjust viscosity. Although the process of choosing additives can be complex and some options can be expensive, Kuraray supports efficient, cost-effective viscosity modification with SEPTON™ and KURARAY LIQUID RUBBER.

Contact