SEPTON™ – The versatile TPE

SEPTON™ is a series of styrenic thermoplastic elastomers developed by Kuraray. SEPTON™ is used in a great number of TPE compounds and can be processed in a wide variety of forms. Specific grades are certified and used in consumer goods, medical, mobility and oil modification applications. These styrenic TPEs cover a broad range of applications including compounds, polymer modification, adhesives, flexible PVC substitutes and vibration damping products.

The Hydrogenated Styrenic Block Copolymers (HSBCs) consist of styrene-based hard blocks and a hydrogenated diene soft block. HSBCs exhibit rubber-like elasticity since the hard block acts as a crosslinking point below the glass transition temperature of polystyrene and the soft block provides elasticity. Hydrogenation generates excellent heat and weather resistance.

Content

- Features and benefits

- Applications

- Standard grades of SEPTON™

- Product brochure / technical information

- Septon Specialty Grades

- Contact

Features

- Excellent mechanical properties

- UV-/Weather resistant

- Good resistance to chemicals

- Good low temperature performance

- Non-toxic

- High heat resistance

- Excellent electrical insulation

- Rubber-like elasticity

- Recyclable

Benefits

- Easy processing

- Durability

- Long-term quality

- Safety

- Replacement of rubber by TPE

- Replacement of PVC by TPE

Applications

- Adhesives, coatings, sealants

- Compounding

- Consumer goods

- Electronics

- Industrial & construction

- Medical

- Mobility

- Oil modification

- Sporting goods & footwear

- 3D printing

Standard grades of SEPTON™

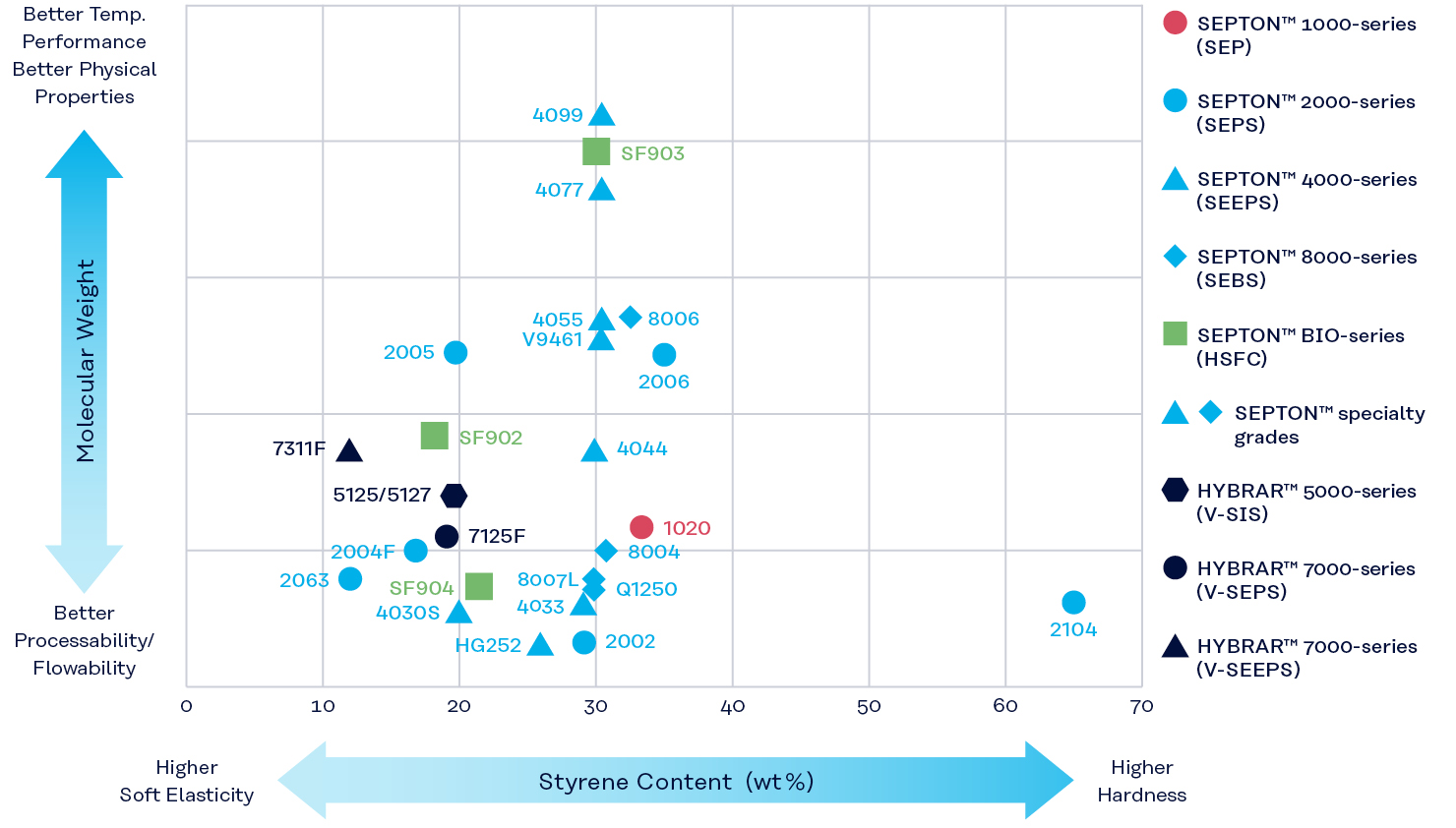

SEPTON™ is offered in a variety of grades, from low to high styrene content and from low to ultra-high molecular weight. Also, in terms of soft-block structure, there are four different types, SEP, SEPS, SEEPS and SEBS.

There is a variety of SEPTON™ grades, from low styrene content (soft) to high styrene content (rigid), from low molecular weight (high flow) to high molecular weight (more rubber-like properties). Each provides different functional characteristics and can be used in various applications. These products exhibit rubber-like properties over a broad temperature range. In comparison to non-hydrogenated styrenic block copolymers, SEPTON™ exhibits better tensile strength, better heat, weather and ozone resistance as well as better compatibility with poly-olefins.

SEPTON™ 1000-series (SEP)

SEPTON™ 1000-series is a di-block type. It is characterized by excellent transparency and good flow ability due to its SEP structure (SEP; styrene-ethylene-propylene). Main areas of application are adhesives, sealing materials, automotive parts, cable and wire insulation, cosmetics, oil modification and viscosity index improvers (VII). SEPTON™ 1000-series products can also be applied as a modifier for unsaturated polyester.

| Grade | Type | Styrene Content (wt%) | MFR | Solution viscosity (Toluene solution 30 °C) | Physical form | Hardness type A |

|||

| 230 °C, 2.16 kg (g/10min) | 200 °C, 10 kg (g/10min) | 5wt% (mPa·s) | 10wt% (mPa·s) | 15wt% (mPa·s) | |||||

| 1020 | SEP | 36 | – | 1.8 | – | 40 | – | Crumbs | 70 |

SEPTON™ 2000-series (SEPS)

The SEPS structure (SEPS; styrene-ethylene-propylene-styrene) generally does not crystallize and exhibits excellent tensile elongation and low temperature properties. With its broad range of hardnesses, SEPTON™ 2000-series is used with various products like adhesives, personal electronics, medical and consumer goods such as diapers.

| Grade | Type | Styrene Content (wt%) | MFR | Solution viscosity (Toluene solution 30 °C) | Physical form | Hardness type A |

|||

| 230 °C, 2.16 kg (g/10min) | 200 °C, 10 kg (g/10min) | 5wt% (mPa·s) | 10wt% (mPa·s) | 15wt% (mPa·s) | |||||

| 2002 | SEPS | 30 | 70 | 100 | – | – | 25 | Pellet | 80 |

| 2004F | SEPS | 18 | 5 | – | – | – | – | Pellet | 67 |

| 2005 | SEPS | 20 | No flow | No flow | 40 | 1700 | – | Crumbs | – |

| 2006 | SEPS | 35 | No flow | No flow | 27 | 1220 | – | Crumbs | – |

| 2063 | SEPS | 13 | 7 | 18 | – | 29 | 140 | Pellet | 36 |

| 2104 | SEPS | 65 | 0.4 | 22 | – | – | 22 | Pellet | 98 |

SEPTON™ 4000-series (SEEPS)

The unique SEPTON™ 4000-series (SEEPS; styrene-ethylene-ethylene-propylene-styrene) offers better tensile strength, oil retention and PE compatibility than SEBS (styrene-ethylene-butylene-styrene). The products show also moderate elongation with exceptional oil absorbency.

Additionally, the SEPTON™ 4000-series features a variety of molecular weight grades. The high molecular weight version provides robust tensile strength and compression set. The products are suitable for many different applications like: mobility, consumer goods such as cosmetics and diapers, sporting goods and medical applications. Rubber-like compounds with SEPTON™ 4000-series products can also replace PVC in several applications.

| Grade | Type | Styrene Content (wt%) | MFR | Solution viscosity (Toluene solution 30 °C) | Physical form | Hardness type A |

|||

| 230 °C, 2.16 kg (g/10min) | 200 °C, 10 kg (g/10min) | 5wt% (mPa·s) | 10wt% (mPa·s) | 15wt% (mPa·s) | |||||

| 4030S | SEEPS | 20 | 1.0 | 1.5 | – | 81 | – | Crumbs | 67 |

| 4033 | SEEPS | 30 | < 0.1 | < 0.1 | – | 50 | – | Crumbs | 76 |

| 4044 | SEEPS | 32 | No flow | No flow | 22 | 460 | – | Crumbs | – |

| 4055 | SEEPS | 30 | No flow | No flow | 90 | 5800 | – | Crumbs | – |

| 4077 | SEEPS | 30 | No flow | No flow | 300 | – | – | Crumbs | – |

| 4099 | SEEPS | 30 | No flow | No flow | 670 | – | – | Crumbs | – |

SEPTON™ 8000-series (SEBS)

With its popular mid-block structure in HSBCs, SEPTON™ 8000-series (hydrogenated SEBS type) is an excellent choice. The moderate tensile strength is one of the main features of SEBS. The SEPTON™ 8000-series is widely used for automotive and personal care products.

| Grade | Type | Styrene Content (wt%) | MFR | Solution viscosity (Toluene solution 30 °C) | Physical form | Hardness type A |

|||

| 230 °C, 2.16 kg (g/10min) | 200 °C, 10 kg (g/10min) | 5wt% (mPa·s) | 10wt% (mPa·s) | 15wt% (mPa·s) | |||||

| 8004 | SEBS | 31 | < 0.1 | < 0.1 | – | 40 | – | Crumbs | 80 |

| 8006 | SEBS | 33 | No flow | No flow | 42 | – | – | Crumbs | – |

SEPTON™ HG-series (SEEPS-OH)

SEPTON™ HG-series (SEEPS-OH; hydroxyl group containing styrene-ethylene-ethylene-propylene-styrene) features a hydroxyl group on one end. As a result, the reaction can be controlled. SEPTON™ HG252 is used as a modifier for polar resins and compatibilizer of polar/non-polar resins.

| Grade | Type | Styrene Content (wt%) | MFR | Solution viscosity (Toluene solution 30 °C) | Physical form | Hardness type A |

|||

| 230 °C, 2.16 kg (g/10min) | 200 °C, 10 kg (g/10min) | 5wt% (mPa·s) | 10wt% (mPa·s) | 15wt% (mPa·s) | |||||

| HG252 | SEEPS-OH | 28 | 26 | – | – | – | 70 | Pellet | 80 |

Product brochure

SEPTON™

HYBRAR™

Technical insights

You can find more information about our products and applications in the R&D documentation.

SEPTON™ Specialty Grades

Using its proprietary polymer synthesis and modification technologies, Kuraray has developed several unique SEPTON™ grades. Those series cover a broader range of product properties like for example super soft application possibilities with SEPTON™ J-series or a superior heat resistance provided by SEPTON™ V-series.

Kuraray has developed a new family of hydrogenated styrene farnesene block copolymers (HSFC) called SEPTON™ BIO-series. SEPTON™ BIO-series is synthesized from beta-farnesene, a renewable monomer derived from sugarcane. It can muster a bio-based content of up to 80%. SEPTON™ BIO-series lends itself to a broad range of applications like TPE compounds and sporting goods, such as swimming equipment and footwear. By using SEPTON™ BIO-series, customers can achieve an optimized carbon footprint compared to conventional TPEs on the market. For further information, please contact us.

SEPTON™ Q-series is a range of thermoplastic elastomers that combines softness and elasticity. Compounds with SEPTON™ Q-series products as the base polymer have very good mechanical properties and are lighter than conventional materials. The materials from Kuraray have considerably lower density than other engineering TPEs such as thermoplastic polyurethane (TPU) and thermoplastic amide elastomers (TPAE).

SEPTON™ V-series is a block copolymer that has reactive and cross-linkable hard and soft block. Crosslinked SEPTON™ V-series exhibit excellent heat resistance, long term compression set and oil resistance while keeping its good rubber-like properties and good low temperature properties due to crosslinked hard block. Compared to standard grades of SEPTON™, SEPTON™ V-series significantly improves the heat resistance of styrenic thermoplastic elastomers.

SEPTON™ J-series is Kuraray’s specialty product for high performance gels. Its excellent shock absorbing and damping properties combined with its non-allergenic qualities meet the high demands for those products. Characteristics like a lower melt viscosity, excellent low temperature behavior and superior processability at a low shear rate ensure an enhanced processability and flexible compounds.

SEPTON™ F-series is Kuraray’s latest development for the Personal Care & Hygiene industry. Kuraray‘s latest development is considered a key differentiating factor of elastic components in diapers to combine strong holding power with less waste and Kuraray’s unique technology to protect babies’ skin.

Contact