HYBRAR™

HYBRAR™ is a truly unique block-copolymer consisting of polystyrene end blocks and a vinyl bonded rich poly-diene mid-block. Due to its peak tan delta over a broad temperature range, HYBRAR™ exhibits high vibration damping and shock absorption properties.

Unlike PVC, products manufactured using HYBRAR™ do not need a plasticizer, which reduces the environmental impact of the whole supply chain. The highly elastic styrene block copolymer HYBRAR™ can be processed in a wide variety of forms, including films, tubes and injection molding.

HYBRAR™ products are available as hydrogenated and non-hydrogenated grades. Hydrogenated grades of HYBRAR™ have excellent compatibility with polypropylene resulting in excellent transparency and clarity when blended.

Content

Features

- Excellent vibration damping over a broad temperature range

- High affinity for polyolefins and polystyrene

- Good moldability

- Can be cross-linked like vulcanizable rubber

- Rubber-like elasticity

- Very good heat and weather resistance

- Alternative to PVC

- No additional plasticizers required

Benefits

- Noise reduction, shock absorption and impact resistance due to extraordinary damping properties

- Hydrogenated grades (HYBRAR™ 7000-series) provide excellent transparency as a polypropylene blend

- Excellent weather and heat resistance

- Non-toxic

- Environmentally friendly compared to PVC

- Medical films and tubing made with HYBRAR™ have much less environmental impact during production and disposal than PVC

- Highly suitable for medical, sports equipment, automotive and acoustic components as well as flooring

Applications

- Coatings

- Compounding

- Food and packaging

- Industrial and construction

- Medical

- Mobility

- Sporting goods and footwear

- 3D printing

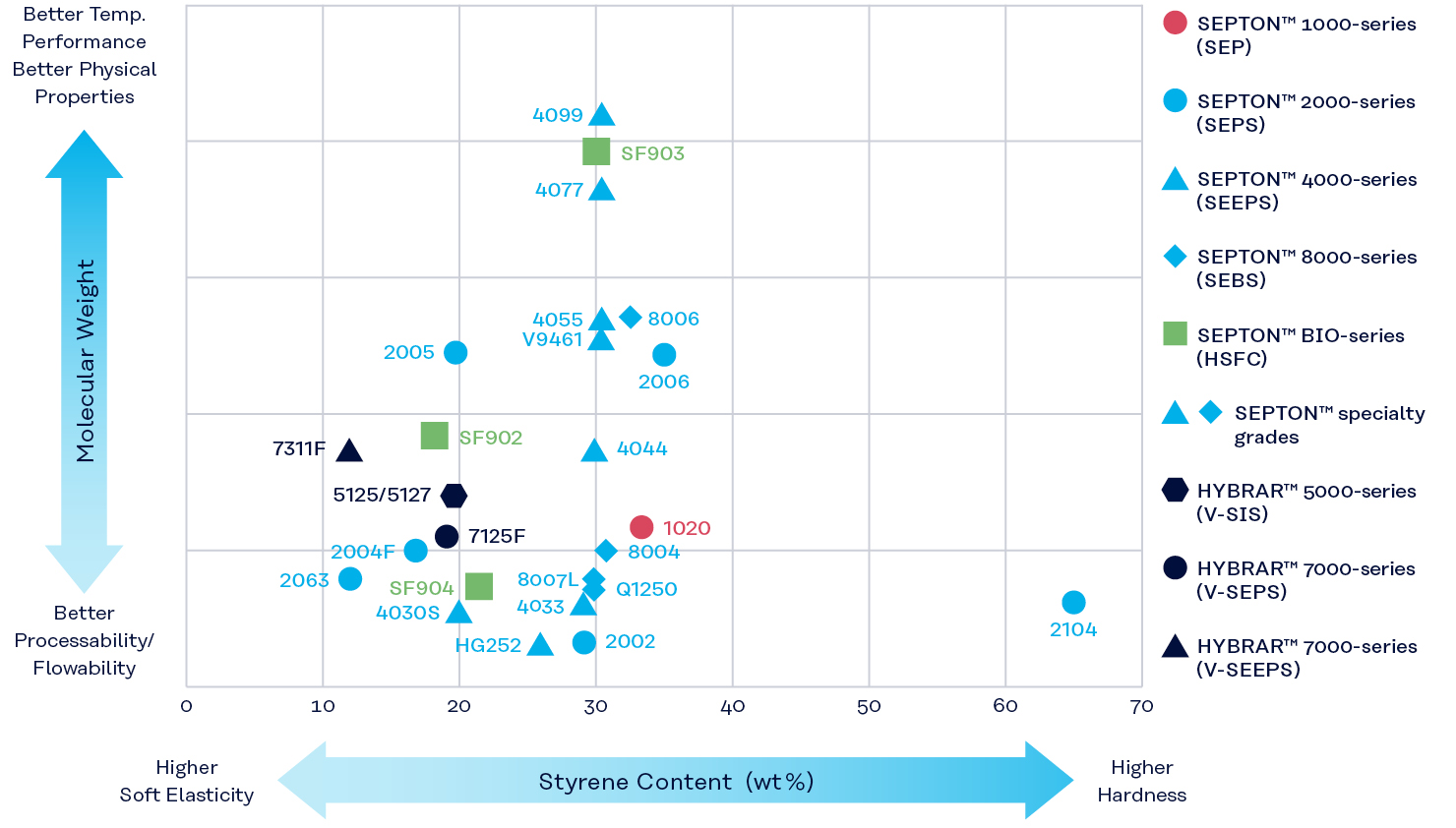

Grades of HYBRAR™

HYBRAR™ products are available as durable hydrogenated grades (HYBRAR™ 7000-series) and non-hydrogenated grades (HYBRAR™ 5000-series). The hydrogenated grades show excellent compatibility with polypropylene resulting in improved transparency, clarity and flexibility. Flexible films manufactured using a blended material of a hydrogenated grade and polypropylene are more environmentally friendly than soft-PVC due to the absence of harmful plasticizers.

HYBRAR™ exhibits high damping performance at a broad temperature range. Its enhanced damping properties make HYBRAR™ the product of choice for shock absorption in sports equipment, footwear as well as foamable sound damping sealants. Other applications include electronic components, film and tubing for medical, adhesives, coatings, sealants, hearing protection, automotive and housing as well as construction.

All HYBRAR™ grades are pretty similar in molecular weight, most of them are low to medium molecular weight. To prevent oxidation and yellowing, special hydrogenated grades are commonly used in medical applications.

Hydrogenated grades

The hydrogenated grades of the HYBRAR™ 7000-series (Vinyl-bond rich SEPS or SEEPS) provide an excellent heat and weather resistance. HYBRAR™ has good compatibility with polypropylene so that such blends offer excellent transparency with good flexibility. It is used in films, sheets, extrusion parts (tubes, cables), injection parts and other products as an environmentally friendly softener material without the need for a plasticizer, in contrast to soft PVC.

Hydrogenated grades (HYBRAR™ 7125F and HYBRAR™ 7311F) exhibit excellent compatibility with polypropylene. Unlike soft PVC, they offer good flexibility and mechanical properties without the need for plasticizers and are therefore friendlier to the environment.

HYBRAR™ 7311F has a lower styrene content and a lower glass transition temperature than HYBRAR™ 7125F. As a result, PP/7311F blends are more flexible at room temperature than PP/7125F blends and offer better impact properties at lower temperatures.

The hydrogenated grades show excellent compatibility with polypropylene resulting in improved transparency, clarity and flexibility when blended.

| Grade | Type | Styrene Content (wt%) | Tg (°C) | MFR | Solution viscosity (Toluene solution 30 °C) | Physical form | Hardness type A |

|||

| 190 °C, 2.16 kg (g/10min) | 230°C, 2.16 kg (g/10min) | 15wt% (mPa·s) | 20wt% (mPa·s) | 30wt% (mPa·s) | ||||||

| 7125F | Vinyl-bond rich SEPS | 20 | -15 | 0.7 | 4 | – | 60 | 350 | Pellet | 64 |

| 7311F | Vinyl-bond rich SEEPS | 12 | -32 | 0.5 | 2 | 95 | 240 | – | Pellet | 41 |

Non-hydrogenated grades

HYBRAR™ 5000-series is a non-hydrogenated and vinyl-bond rich styrene isoprene styrene (SIS) copolymer. The vinyl content affects glass transition temperature (Tg) and is the reason why HYBRAR™ 5000-series is highly recommended for applications where high damping is needed. Each non-hydrogenated HYBRAR™ grade (HYBRAR™ 5125 and HYBRAR™ 5127) has a peak of damping performance in different temperature ranges. For applications where double-bonds for reactions are needed, HYBRAR™ 5000-series is an excellent choice.

Taking advantage of this damping performance, the HYBRAR™ 5000-series is used in damping foam sealants, sports products and footwear. Other potential applications are electronic parts, building materials, household appliances, automotive parts, adhesives, coating agents and sealing materials.

| Grade | Type | Styrene Content (wt%) | Tg (°C) | MFR | Solution viscosity (Toluene solution 30 °C) | Physical form | Hardness type A |

|||

| 190 °C, 2.16 kg (g/10min) | 230°C, 2.16 kg (g/10min) | 15wt% (mPa·s) | 20wt% (mPa·s) | 30wt% (mPa·s) | ||||||

| 5125 | Vinyl-bond rich SIS | 20 | -13 | 3 | – | – | 100 | 650 | Pellet | 60 |

| 5127 | Vinyl-bond rich SIS | 20 | 8 | 3 | – | – | 85 | 540 | Pellet | 84 |

Product Brochure

SEPTON™

HYBRAR™

Technical insights

You can find more information about our products and applications in the R&D documentation.

Contact