SEPTON™ BIO-series: New styrenic elastomer using renewable monomer

With SEPTON™ BIO-series, Kuraray offers a unique hydrogenated styrene farnesene block copolymer (HSFC) – which makes us the first and only manufacturer of bio-based HSBC materials on the market. As one of the leading suppliers of TPEs, we are responding to increasing industry demand for more sustainable materials that can significantly improve the environmental footprint of products made with them. For example, the production of these novel TPE materials has much lower greenhouse gas emissions compared to conventional styrenic block copolymers.

With SEPTON™ BIO-series, Kuraray gives manufacturers a new solution that enables new compounds and end-uses with a high bio-based content to expand existing market areas and open up new ones. So far, Kuraray has achieved a bio content in SEPTON™ BIO-series of up to 80%. Further investigations are focused on maximizing the bio-based content and finding additional synergies with other bio-based raw materials. Kuraray is continuously working on improving the physical properties of these TPE materials to open up new fields of applications for its customers.

How it’s made

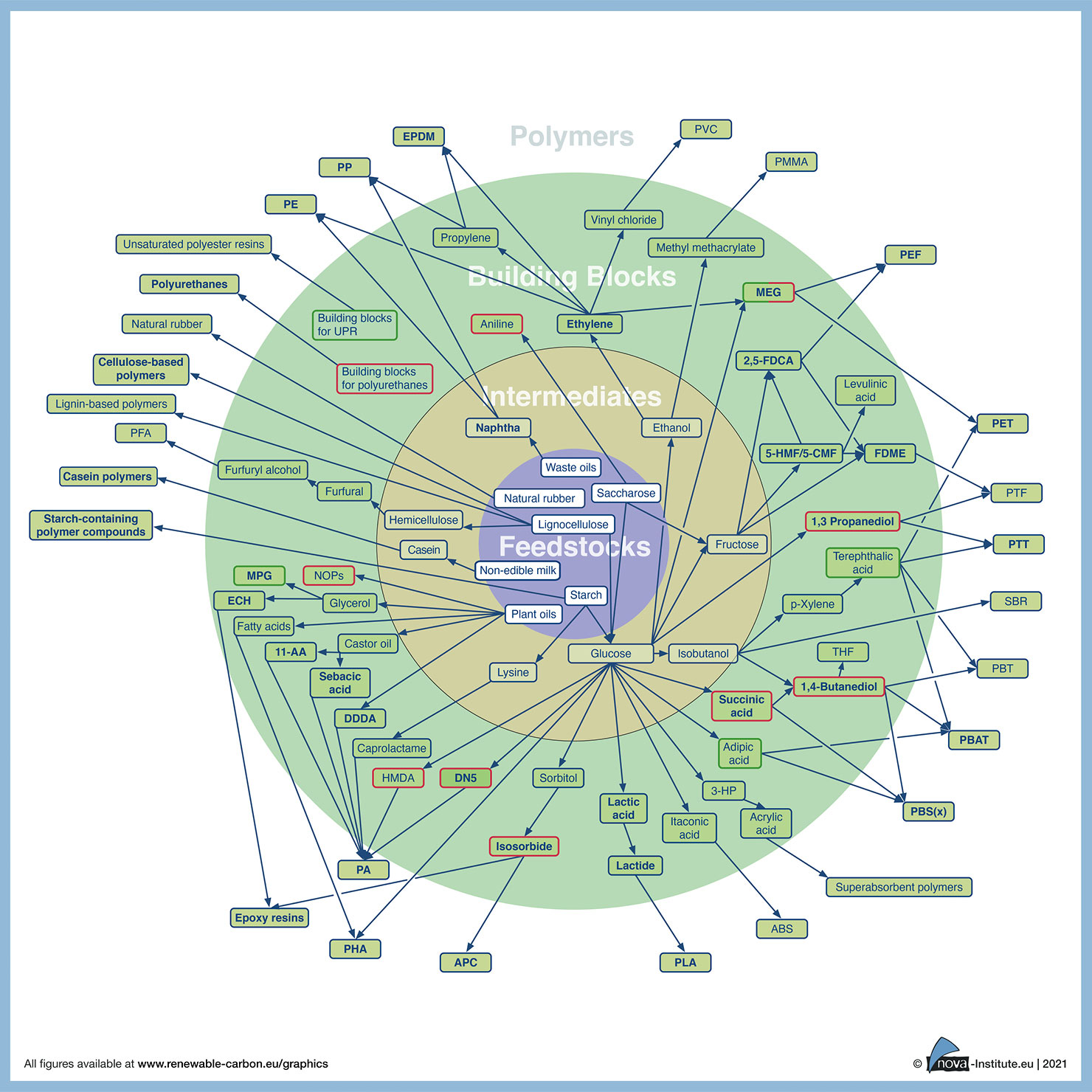

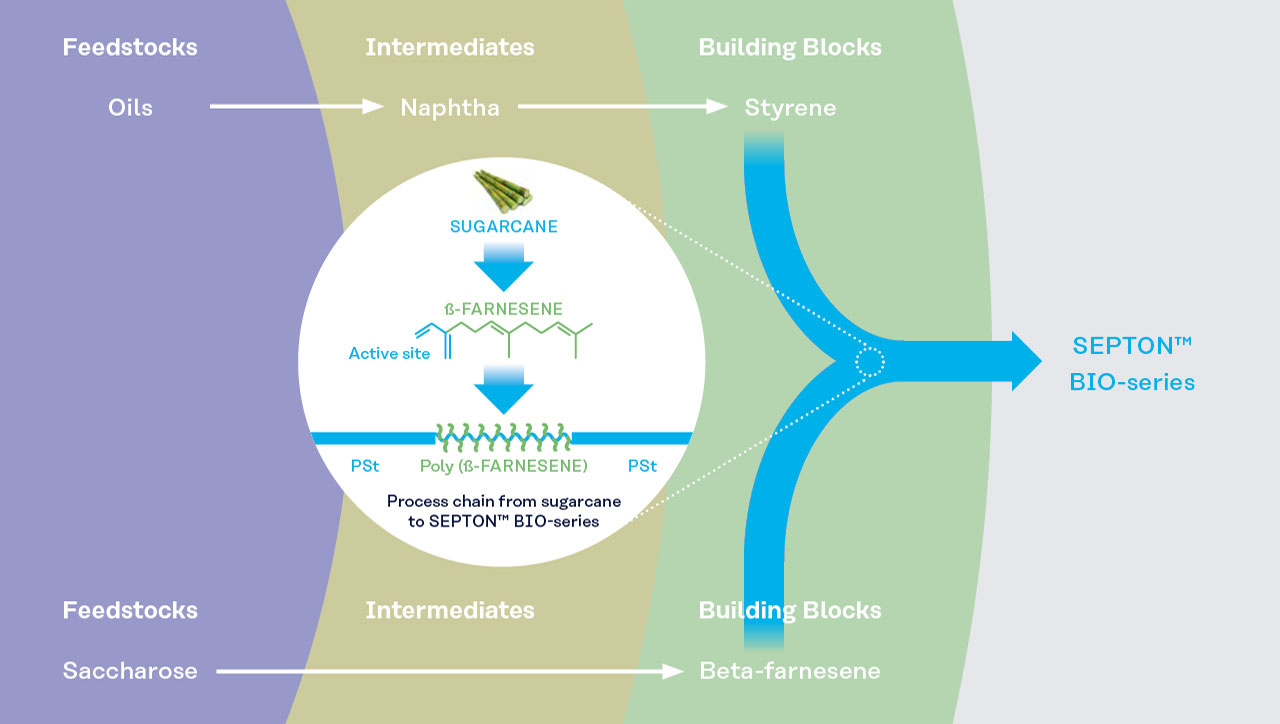

SEPTON™ BIO-series is a new family of hydrogenated styrene farnesene block copolymers (HSFC), which is based on natural, renewable resources. SEPTON™ BIO-series utilizes a new, bio-based monomer called beta-farnesene, which is derived from the fermentation of sugar from sugar cane. Through established fermentation processes, proprietary yeast strains convert sugar sources into beta-farnesene. When beta-farnesene is polymerized, its unique chemical structure differs from conventional hydrogenated styrene block copolymers (HSBCs). SEPTON™ BIO-series thus allows the development of TPEs that are more sustainable than conventional materials on the market and enables users to increase the bio content of TPEs compared to petroleum-based materials.

There are different pathways in the production of bio-based polymers. © nova-Institut GmbH

Features and benefits

- Bio-based polymer with up to 80% bio content

- Lower greenhouse gas emissions than conventional SEBS/SEEPS

- Excellent wet and dry grip performance

- Strong and stable adhesion force across a wide temperature range

- Good processability

- Good damping properties over a wide temperature range

- Low compression set, low permanent set

- Low oil bleed

- Enables adhesive applications with excellent removability and no residue

A significant advantage and decisive added value of SEPTON™ BIO-series compared to conventional materials available on the market are the significantly lower greenhouse gas emissions. These are up to 33% lower than standard SEBS and SEEPS.

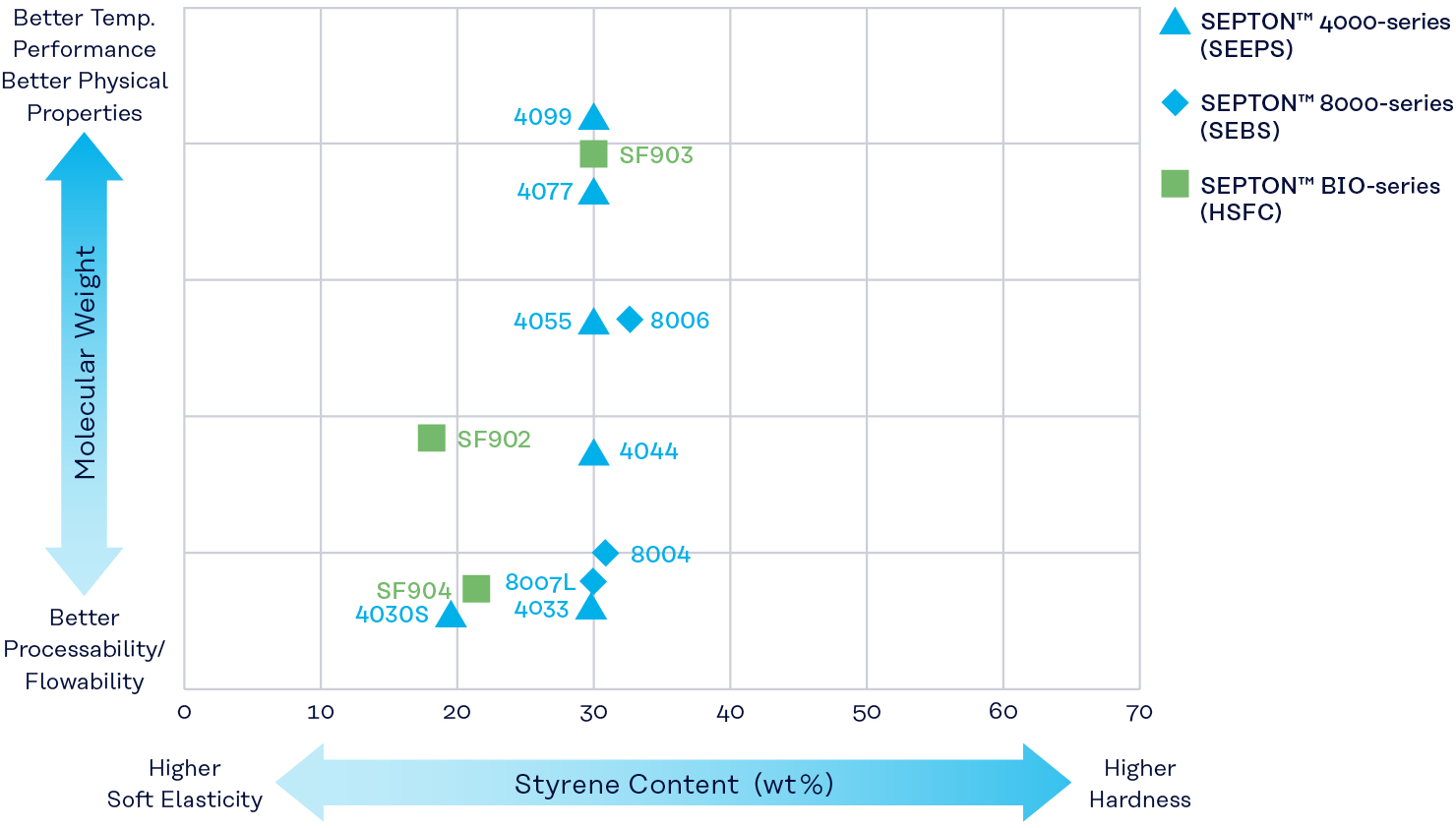

The grades of SEPTON™ BIO-series vary by molecular weight and bio content. We offer grades with a bio content of up to 80%.

Assumptions and limitations

- LCA for SEPTON™ BIO-series was conducted based on the production conditions expected by Kuraray at target volumes.

- This LCA information may be subject to revision as new knowledge and experience becomes available.

- Kuraray makes no warranties and assumes no liability in connection with any use of this LCA information.

With the help of SEPTON™ BIO-series, users can substantially increase the bio content in their products compared to petroleum-based compounds. The new materials have differentiated performance and can be designed for existing and new applications.

Compared to most HSBCs, SEPTON™ BIO-series exhibits higher flow ability, good adhesion, lower hardness without plasticizers, good permanent and compression set, high grip performance and improved damping properties over a wide temperature range.

Applications

Important application areas for SEPTON™ BIO-series are the consumer goods sector, where TPE compounds with a high bio-based content are increasingly in demand, and the adhesives sector.

Today, sustainability is an important purchasing criteria for example for shoes. In a survey by the Statista market research organization, 80% of respondents said that sustainability influences their decisions to buy clothing.

Kuraray’s SEPTON™ BIO-series made from bio-based monomers offers footwear manufacturers a sustainable, high-performance alternative that is superior to conventional TPEs in many ways. The SEPTON™ BIO-series provides benefits for many components of shoes thanks to its outstanding properties, which include high elasticity and damping. When used as starting products for shoe soles, these copolymers give very good grip. Their wet grip and performance over a wide temperature range are far superior to conventional TPEs.

For certain applications, SEPTON™ BIO-series cannot be introduced due to raw material supply relations. Please contact our sales representatives.

Applications

- Adhesives, coatings, sealants

- Compounding

- Consumer goods

- Electronics

- Industrial & construction

- Mobility

- Sporting goods & footwear

- 3D printing

Ethical

The use of food crops for the production of bio-based polymers is a recurring debate. Here, a distinction must be made between so-called food crops and cash crops. The latter are grown for direct sale on the market, also as raw materials for the processing industry, but not for family consumption or as livestock feed. Sugar cane is included, as are coffee, tea, and cocoa. The term food crops, on the other hand, refers to the world’s major food products derived from plants and used to meet global food needs. Cereals, legumes, vegetables, tubers and fruits are among them. Since SEPTON™ BIO-series is based on sugar cane, a cash crop, it does not exacerbate the global hunger problem, while bio-based polymers made from food crops such as potatoes or cereals can.

The sugar cane cultivation used to produce the beta-farnesene for SEPTON™ BIO-series is certified by Bonsucro, a label for environmentally and socially responsible sugar cane cultivation. The Bonsucro production standard is the most widely used performance framework for sugar cane in the world. It contains principles and criteria to achieve sustainable production of sugar cane and all products derived from sugar cane in terms of economic, social and environmental dimensions.

Sustainability brochure

SEPTON™ BIO-series

Technical insights

You can find more information about our products and applications in the R&D documentation.

Contact