ISOBAM™: Water-soluble polymer

ISOBAM™ is an alkali water-soluble copolymer of isobutylene and maleic anhydride. The material, which has a white, powdery appearance, has outstanding properties that conventional water-soluble polymers such as polyvinyl alcohol and cellulose derivatives have not yet achieved. ISOBAM™ reacts with chemicals such as sodium hydrate, ammonia and amine and can be used as an aqueous solution.

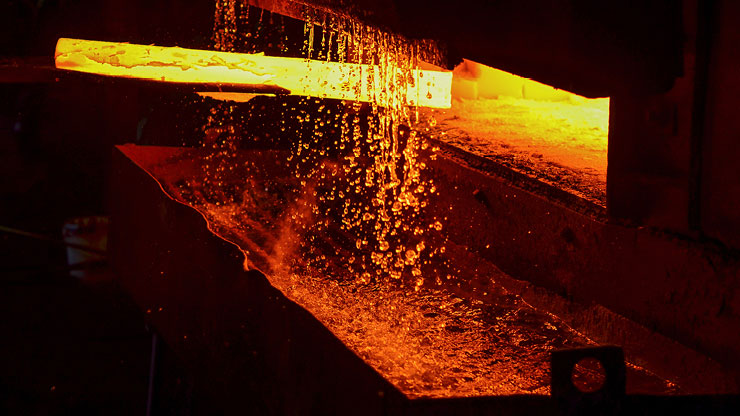

An important field of application for ISOBAM™ is metal processing, where it is used as a forging lubricant and quenching fluid. With excellent water resistance and tackiness, it can also be used as an adhesive, in glass fibers, as a binder for ceramic powders and in other applications.

Features and benefits

- Water-soluble polymer

- Solvent-free

- Non-Pigment Forging Lubricant (NPFL) additive

- Excellent heat and water resistance

- Environmentally friendly compared to oil

Applications

- Metal processing

- Adhesives

- Glass fibers

- Binder for ceramics

Types of ISOBAM™

Standard type

The standard type of ISOBAM™ is used as a binder with excellent heat resistance and hardness. It is further characterized by an excellent dispersing effect, with high functionality of the carboxyl group in the molecule. Standard types have a molecular weight ranging from medium to high and are soluble only in alkaline solutions.

Amide-ammonium salt type

The amide-ammonium salt types of ISOBAM™ are ammonium modified products based on the standard grade. In addition to the properties of the standard type of ISOBAM™, they are soluble in regular water. With the amide-ammonium salt types, the pH of the aqueous solution is neutral.

Imide type

The imide types of ISOBAM™ are imide-degenerated products based on the standard types. Due to their particularly good properties – their excellent water and heat resistance – they are used in wood adhesives.

Applications

Metal processing

ISOBAM™ is used in metal processing as a forging lubricant to replace forging oils, and as a quenching fluid where it replaces quenching oils. In these applications, ISOBAM™ contributes to high production safety and product quality and prevents fire hazards and flying sparks.

Oil-based die lubricants with or without graphite cause severe contamination during hot forging as a result of heavy smoke generation. In forging shops, oil can leak out and contaminate the surroundings.

If, on the other hand, water-soluble, graphite-free hot forging lubricants based on ISOBAM™ are applied with a spray system, there are many advantages, such as no pollution of the environment, no settling of particles or no coagulation of the lubricant, since ISOBAM™ is water-soluble. In addition, water-soluble hot forging lubricants are more environmentally friendly and better for the working environment.

Features and benefits

- Improves processability of metal

- Spark and fire prevention

- Prevents corrosion

- Cooling improves steel morphology

- Reduced residue

- Less smoke and odor compared to oil-based lubricants

- Safer than oil, sparking fire prevention

- Health-friendly compared to oil

Adhesives

Aqueous solutions of ISOBAM™ are used to prepare polyvinyl acetate (PVAC) emulsions as protective colloids. Aqueous ISOBAM™ can also be added to the emulsion as an adhesive component. As a result of its high heat resistance and high tackiness, ISOBAM™ is used, for example, as an additive for PVA-based wood adhesives to improve the properties of chipboard.

Features and benefits

- Improvement in film rigidity and strength*

- Improvement in bonding strength*

- High initial tack**

- High bonding strength**

- Can be cross-linked to achieve superior water resistance**

* Adhesives from PVAC emulsion using ISOBAM™ as a protectivecolloid

** Adhesives from a blend of PVAC emulsion and ISOBAM™

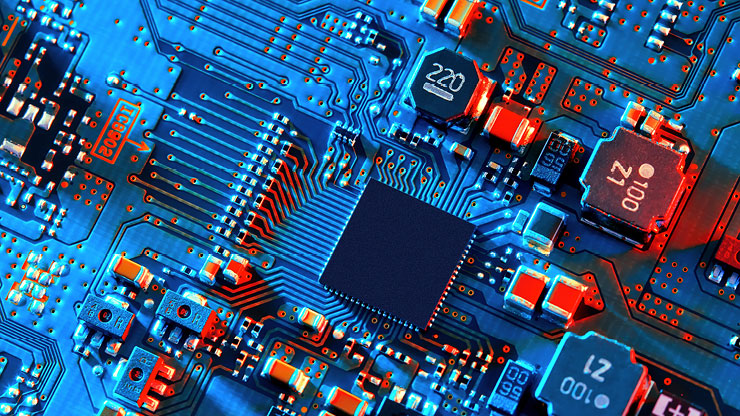

Glass fibers

Glass fibers can be used in an extremely wide range of applications. The spectrum ranges from printed circuit boards and automotive applications to wind turbine rotor blades and cement production, where glass fibers are used instead of asbestos. In the production of glass fibers and glass fiber reinforced plastics and composites, it is necessary to bundle the fibers for better handling. For this purpose, ISOBAM™ is used as a binder and dispersant. ISOBAM™ also simplifies metering in compounds. Furthermore, the dispersion and adhesion of the fibers in the plastic matrix can be adjusted.

Glass fibers are “dipped” in the aqueous solution of ISOBAM™, which makes them blend better with plastic. For example, PA can be reinforced with a content of up to 70% glass fibers. Glass fiber-reinforced plastics are also interesting for materials that replace metals in the automotive industry or in composite technology.

Features and benefits

- Improved adhesive force between glass fibers and resin

- Enhanced water resistance

- Lower-yellow index

Binder for ceramics

In the production of ceramics, various additives and agents are used as dry mixes or slurries. The binder has the function to obtain a stable green strength of the pressed or cast part before cutting and firing. As a water-soluble binder and dispersant for ceramic powder in the slurry, ISOBAM™ improves the green strength, porosity and density of the parts.

Features and benefits

- Temporary binder and dispersants agent for ceramics

- Excellent green strength and flexibility at low dosage

- Enables better cutting, less scrap

- Suited for low viscosity slurry with good storage stability

- Water-soluble

- Clean burn-out with low ash content

- Improved compressive strength and flex strength

Further applications

ISOBAM™ has many other uses: as a dispersant for fertilizers or as an additive in the production of specialty papers, battery separators or specialized inks.

If ISOBAM™ could be of interest for another of your applications, please let us know. We would be happy to share our expertise with you.

Product brochure

ISOBAM™ –

Water soluble polymer

Technical insights

You can find more information about our products and applications in the R&D documentation.

Contact