What is a tackifier?

A tackifier, also known as a tackifying resin, is a compound used in adhesive and sealant formulations that increases the stickiness, or tack, of the final product. They are typically resins in solid form with low molecular weight and high softening points, but they can also be found in liquid form. They often make up a significant portion of both the cost and content of adhesive formulations.

From adhesion and cohesion to compatibility with your base polymer and softening point, choosing the right tackifier in the correct concentration is key to developing an adhesive with the properties you need.

Tackifiers for adhesives and sealants

After the base polymer, the tackifier is the most important component of an adhesive. While the base polymer determines the adhesive’s cohesion and elasticity, the tack, or stickiness, comes from the type and concentration of tackifier used. To create a strong product with the right level of tack, a formulation must strike the correct balance between adhesion and cohesion by adjusting the type and amount of tackifier.

Tackifiers are most often used in pressure-sensitive adhesives or hot melt adhesives, but they can also be used in water-based adhesives as resin dispersions, which are usually manufactured by emulsifying the resin in the aqueous solvent. They are also sometimes used to control the properties of products such as tires, rubber, paint, ink, and oil.

Disambiguation: Soil stabilizing tackifiers

Adhesive tackifiers are sometimes confused with soil stabilizers, which may also be called tackifiers. These soil stabilizing tackifiers are hydraulically applied to the ground in areas prone to wind or water erosion to promote soil adhesion, and may include plant materials like starch or resin, polymeric emulsions, or cementitious binders such as gypsum. Although used in binding soil, they are not adhesives in the traditional sense.

Functions of tackifiers

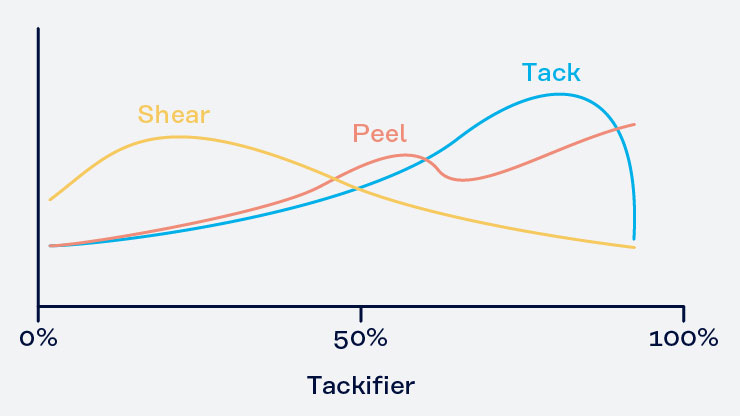

In adhesives and sealants, tackifiers are mixed with base polymers that provide cohesion but lack tackiness or pressure sensitivity. By varying the type and concentration of tackifier, a product’s tack, peel strength, and shear strength can all be modified. Generally, tack and peel strength increases as the concentration of tackifier in an adhesive increase, while shear strength decreases.

- Tack: How quickly an adhesive bond forms between two surfaces under light pressure.

- Peel Strength: The force needed to break a bond between an adhesive and a surface.

- Shear Strength: The ability of a material to resist lateral load that forces it to slide against itself.

Although they primarily adjust tack, adhesion, and cohesion, tackifiers can also affect or be used to modify thermal stability, viscosity, color, and more. Beyond improving tack, they are most often used to improve heat resistance and adhesion to difficult-to-bond substrates.

Properties of tackifiers

Most tackifiers are resins with low molecular weights that make up the sticky, viscous element of an adhesive. They usually have a softening point greater than room temperature, allowing them to be combined with base polymers with a glass transition temperature below room temperature to form a malleable adhesive. Each tackifier has a polarity which largely determines its compatibility with various polymers—although a degree of incompatibility can also be used to achieve a desired physical property.

Types of tackifiers

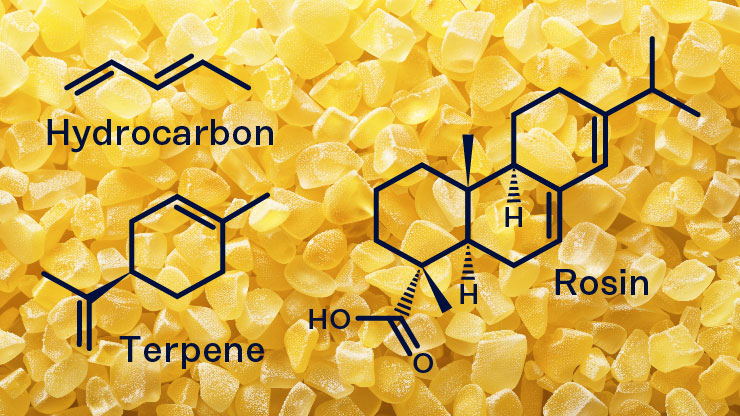

The majority of tackifiers fall into one of three categories: hydrocarbon resins, rosin resins, or terpene resins.

Hydrocarbon resin tackifiers

These tackifiers come from petroleum-based feedstocks, primarily C5 resins and C9 resins. These tackifiers are typically solid at room temperature, and may have a softening point up to 150°C.

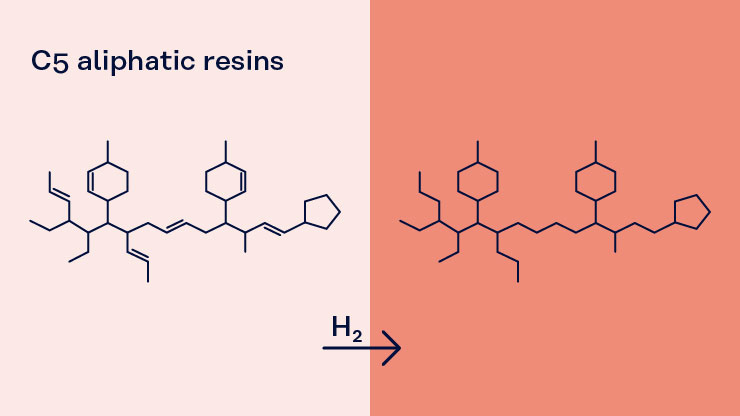

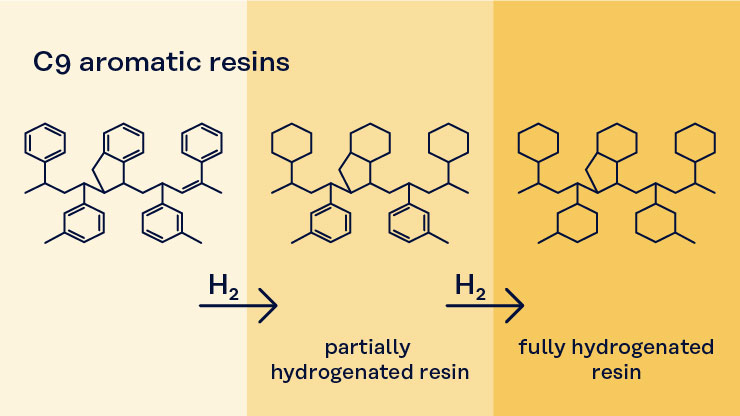

Hydrocarbon resins are either aliphatic (C5), aromatic (C9), or mixed (a blend of C5 and C9). Both C5 and C9 resins may have a wide range of molecular weights and softening points. To fine-tune the resin’s material properties, C5 and C9 resins are often mixed to achieve the desired aliphatic/aromatic ratio, which has a significant impact on the product’s polymer compatibility.

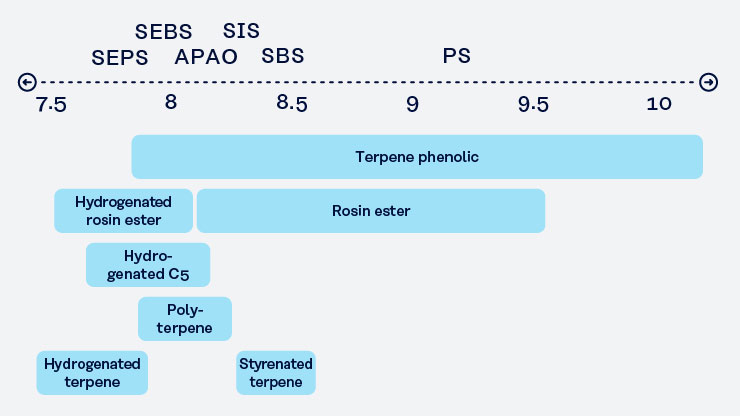

Hydrocarbon resin tackifiers may also be fully or partially hydrogenated to improve their stability and color. Partially hydrogenated C9 resins are hydrogenated to a specific percentage of aromaticity to fine-tune their properties. Fully hydrogenated hydrocarbon resins are aliphatic and have excellent colorability and stability, although their compatibility is limited. They have ideal compatibility with styrenic block copolymers (SBCs) such as SIS, SBS and SEBS, ethylene-vinyl acetate (EVA), amorphous poly-alpha-olefin (APAO) and polyolefin elastomers (POEs).

Rosin resin tackifiers

Rosin acids and esters are molecules produced from pine trees, including pine gum, wood rosin, and tall rosin oil. Since these materials are renewable and pine gum can even be collected from living trees, there is growing interest in rosin resin as a sustainable, bio-based additive.

Rosin resins are compatible with almost all polymer types and are often used as tackifiers with ethylene vinyl acetate, polyurethanes, acrylics, and more to produce hot melt adhesives and water-based adhesives. Their flexibility is supported by their wide variety of molecular weights and softening points, which typically range from room temperature to 150°C. Although rosin resins provide excellent tack and peel adhesion, they usually decrease the cohesion of a formulation.

Unsaturated rosin resin tackifiers are often modified to improve their properties. Hydrogenated rosins offer significantly improved stability, lighter color, and UV resistance, and they only slightly decrease the cohesion of the final formulation. Esterified rosins have improved oxidative and color stability, a wide range of softening points and compatibility, and improved odor. Depending on the alcohol used, esterification allows for further fine-tuning of properties such as softening point and molecular weight.

Terpene resin tackifiers

Terpene resins are derived from alpha-pinene or beta-pinene from pine trees, or d-limonene from the citrus sources. The resins are compatible with a wide variety of polymers including polyolefins, ethylene-vinyl acetate, acrylic, and more.

Generally, terpene resins are polymers with low molecular weight and a higher softening point than most tackifiers, giving them improved heat resistance. They are a popular choice due to their strong adhesion, good color, and heat resistance. Terpene resins can be separated into several subcategories, including:

- Polyterpene: strong adhesion and high heat resistance.

- Styrenated terpene: excellent stability and color, broader compatibility, and low odor. Good compatibility with styrenic block copolymers.

- Terpene phenolic resin: strong adhesion and bonding to difficult-to-bond substrates, excellent compatibility with polar materials, and high softening point.

Advantages of tackifiers (by type)

Hydrocarbon resins are less expensive, rosin resins are versatile and affordable, and terpene resins are a useful option offering high cohesion.

Hydrocarbon resin tackifiers

Hydrocarbon resins offer strong adhesion at a lower price than rosin or terpene resins. They have good aging resistance, especially when hydrogenated, and can even be colorless. These tackifiers can also be modified to tailor their softening point, molecular weight, and compatibility.

Rosin resin tackifiers

Rosin resins impart strong tack and peel adhesion and come in a wide range of softening points and molecular weights, making them compatible with almost all polymers. Hydrogenated and esterified rosins offer good oxidative and color stability, and the properties of esterified rosins can be fine-tuned through the alcohol used in esterification. Rosin resin tackifiers are also bio-based and renewable.

Terpene resin tackifiers

Terpene resins offer nearly universal compatibility with polymers, strong adhesion, good color, and a high and wide range of softening temperatures that provide improved heat resistance. They are also a bio-based, sustainable material. Like rosin resins, they are a well-established class of tackifiers.

Disadvantages of tackifiers (by type)

Hydrocarbon resins have limited compatibility, rosin resins decrease cohesion, and terpene resins are more expensive.

Hydrocarbon resin tackifiers

The main disadvantage of hydrocarbon resins is their limited polymer compatibility when compared to rosin or terpene resins. Although generally less expensive, these resins are also nonrenewable and linked to the price of oil.

Rosin resin tackifiers

Although they are widely compatible and provide strong adhesion, rosin resins decrease the cohesion of a polymer and are generally unstable when not hydrogenated, leading to worse aging resistance and yellowing. These downsides can be mitigated by esterification or hydrogenation, which provides greatly improved stability and minimizes the decrease in cohesion.

Terpene resin tackifiers

Although terpene resins have no notable technical disadvantages as tackifiers, their wide range of uses and limited feedstock give them a somewhat higher price than other options.

Advantages and Disadvantages of Tackifier Types

Need a range of adhesive polymers and tackifier options?

Get in touch with our team at Kuraray to learn more about our versatile range of polar and non-polar adhesive polymers and tackifiers for use in products from hot melt adhesives to water-based sealants.

How to select the best tackifier for your application

The right tackifier will be compatible or miscible with your base polymer, reduce the final adhesive’s modulus, and increase its glass transition temperature.

Base polymer compatibility

Compatibility or miscibility is the most important feature of a tackifier. When a polymer and tackifier are compatible or miscible, they’ll form a uniform material with a single, elevated glass transition temperature. When they aren’t, the resulting material will have a separate polymer Tg and resin Tg. Without the right glass transition temperature and modulus, the adhesive won’t be strong or tacky—there’s no reason to test a combination of polymer and tackifier if they aren’t at least partially compatible.

Solubility is often a useful method of estimating the compatibility or miscibility of a polymer and a tackifier. By comparing the solubility parameters of the two materials, you can estimate whether they are likely to be soluble and develop an adhesive with the required properties.

Modulus reduction

Tackifiers typically have a molecular weight between 300 and 2,000, lower than that of the base polymer. The higher the concentration of the tackifier, the more the polymer network and overall weight of the adhesive are diluted, reducing the modulus. A correct modulus is key to adhesives of every type—it allows pressure-sensitive adhesives to deform and adhere, hot melt adhesives to remain stable at the appropriate temperatures.

Increased glass transition temperature

Adhesives are most effective near their glass transition temperature, so the formulation should have a Tg near the temperature of its intended use. Since base polymers usually have low glass transition temperatures, the right concentration of a tackifier with a higher Tg is critical to a strong, tacky final product.

Stability

Once a tackifier is confirmed to be compatible, it’s also important to ensure that the adhesive will remain stable both during and after production. Additional additives such as antioxidants can also be included to ensure that the adhesive remains strong and tacky.

Tackifier stability is an important consideration in hot melt adhesives, as a poor tackifier may separate or congeal during extended periods of time. Stability is also a critical factor when using emulsified tackifiers in water-based adhesives.

Softening point

The softening point of the tackifier will also affect the final adhesive’s properties. Resins with a high softening point tend to be harder, keeping the adhesive from creeping and improving cohesive strength. Resins with a low softening point will help the final adhesive have increased tack and are better suited to applications where high peel strength is necessary.

A material’s softening point can also affect compatibility—resins with higher softening points are generally less compatible than similar resins with lower softening points.

Other criteria

The tackifier you choose will have significant impacts on the key attributes above, but it may also affect other relevant properties of your final product. Remember to also consider:

- Cost

- Concentration of tackifier required

- Adhesion to any application-specific substrates

- Color and weatherability

- Stability

- Safety and odor

Polymers and tackifiers for adhesives and sealants

Since polymers and tackifiers are the most expensive components in many adhesives and sealants, it’s important to select the correct products for your application. Kuraray offers a variety of flexible polymers that are widely compatible with many formulations.

KURARAY LIQUID RUBBER

As flowable, reactive plasticizers with strong tack, several types of our KURARAY LIQUID RUBBER products find use in hot melt adhesives, pressure-sensitive adhesives, sealants, high-performance coatings, and tires. These colorless, transparent, low-VOC options are a great choice for many adhesives.

KURARITY™, the acrylic TPE

KURARITY™, an exceptionally transparent acrylic block copolymer, exhibits excellent self-adhesion, weatherability, compatibility with polar materials, and residue-less and solvent-free adhesive capability. If you’re planning to use a polar tackifier, KURARITY™ is a great choice—and in certain applications. The strong self-adhesion and natural tack of KURARITY™ enable it to be used without tackifier or plasticizer, streamlining production, limiting costs, and decreasing environmental impact with hot melt coating at lower temperatures or solution coating at higher concentrations. These advantages contribute to energy savings, reduction of VOCs, and increase processability in the manufacturing process.

If the drawbacks of tackifiers are posing a challenge to your application, consider choosing KURARITY™ as a widely compatible and tacky TPE option. If you need a particularly strong adhesive, combine KURARITY™ with a tackifier for a weatherable product with powerful tack.

SEPTON™ and HYBRAR™

SEPTON™ and HYBRAR™ are a series of styrenic thermoplastic elastomers available in a wide variety of grades, molecular weights, and soft block structures. These polymers are excellent choices for use in adhesives that offer great transparency and flow ability. These polymers can offer a wide variety of beneficial properties when used alongside tackifiers, including softness, adhesion stability, and more. SEPTON™ provides even more flexibility as an additive by promoting an adhesive’s ability to adhere to materials ranging from metals to other resins. To help you develop a product with the right adhesive strength for your application, we offer SEPTON™ 8000-series (SEBS), a hydrogenated lineup ideal for compatibility with tackifiers.

To enhance the flexibility of the tackifier you choose, Kuraray’s SEPTON™ line includes SEPTON™ HG-series (SEEPS-OH), a compatibilizer for polar/non-polar resins and a modifier for polar resins.

For versatile polymers that can be paired with almost any tackifier, Kuraray offers both SEPTON™ and KURARITY™, a pair of products covering a wide range of different polarities.

Conclusion

Tackifiers are a key component in adhesive and sealant formulations, and choosing the right polymer and tackifier for your application is key to a tacky, cost-effective, and durable final product. To support your formulations, Kuraray offers a range of adhesive polymers for nearly any application.

Contact