PU soles have conquered the shoe industry—and the market keeps growing

As a single material that offers durability, flexibility, affordability, comfort, and style, polyurethane has quickly become the standard in soles of every kind across the footwear manufacturing industry.

Valued at USD 4.6 billion in 2021, the global PU soles market grew 20% in just two years to USD 5.5 billion in 2023—and is expected to nearly double to USD 10.1 billion by the end of 2030. With over 85% of total global footwear production, the Asian and Pacific market leads in the innovation of PU soles.

Experts anticipate the global polyurethane market volume, driven by increased use in footwear, will grow from 27.1 million metric tons to an impressive 31.3 million metric tons. Read on to learn why polyurethane is the new material of choice.

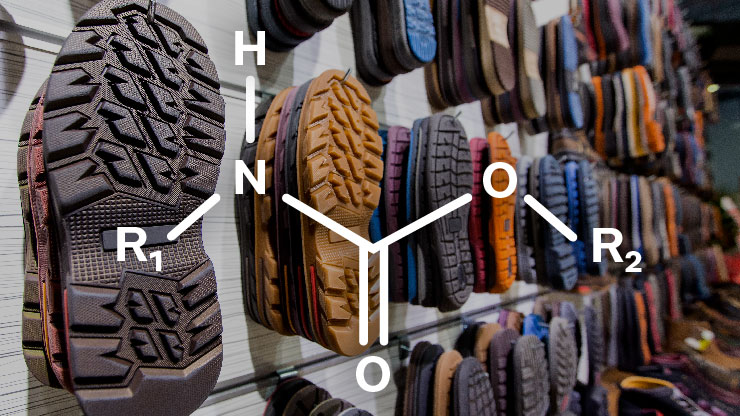

What are polyurethane soles?

Polyurethane soles are an innovative, tailorable class of shoe components that are quickly becoming the preferred choice of footwear manufacturers around the world.

Thanks to their durability, flexibility, and comfort, polyurethane products are widely used for insoles, midsoles, outsoles, and more. You can find polyurethane soles in shoes of every type, from slippers and sneakers to work and safety shoes.

To understand what’s driving their takeover of the footwear manufacturing market, let’s take a look at the various types of PU soles and their benefits. For a differentiated picture, we’ll also cover their disadvantages and how they compare to other common sole materials.

Types of PU soles

PU soles can be tailored to fit a wide variety of applications depending on their type, form factor, chemical basis, and additives.

Solid vs. cellular PU soles

Solid PU soles consist of solid polyurethane, often formed using a mold. These products tend to be shinier, heavier, and tougher and are most often used as outsoles.

Cellular PU soles (also known as foam rubber soles) are produced by injecting an expanding agent into liquid polyurethane, giving it a cellular structure that is spongier and lighter, with lower density and durability. These products are most often used in midsoles and insoles.

Polyurethane soles can also be single pieces with two densities: a softer and more flexible top layer for comfort and a tough, treaded bottom layer for durability.

Polyester vs. polyether PU soles

Polyurethane is produced through a reaction of isocyanates and polyols. Various polyols can be used in this process to adjust the molecular weight and material properties of the resulting polyurethane, which is most commonly either polyester PU or polyether PU.

Polyester PU soles come in densities ranging from 280 to 1,100 g/L and can be used as insoles, midsoles, and outsoles. They offer improved chemical, oil, heat, and abrasion resistance and are often used in safety shoes and sports shoes.

Polyether PU soles are typically around 450 to 600 g/L in density and are often used as monodensity soles. They can be processed at room temperature, have a superior finish, and are water resistant, making them good choices for street shoes and sandals.

Thermosetting (PU) vs. thermoplastic PU (TPU) soles

Thermosetting polyurethane is the most common variety used in soles and the focus of this blog post. Thermoplastic polyurethane, or TPU, is a variant with qualities closer to a rubber that can be melted and reformed, so-called thermoplastic elastomers. TPU is a more expensive option that is less flexible and less slip-resistant, but lightweight, chemical-resistant, and cut-resistant.

PU insoles vs. midsoles vs. outsoles

Polyurethane formulations and production processes are often varied to produce materials suited to insoles, midsoles, or outsoles. Insoles and midsoles are generally lighter, more comfortable, and more flexible, while outsoles tend to be heavier and tougher.

Advantages of PU

Footwear needs to be comfortable, durable, and light, properties that PU soles offer in a convenient, cost-effective package. The many advantages of PU soles make them a great fit for most footwear applications.

Polyurethane soles offer excellent material properties:

- Durable: Since PU soles are tough and abrasion-resistant, they are commonly used in soles of every type. Their durability makes them a longer-lasting option than almost any other sole material.

- Lightweight: PU soles are extremely light and come in a variety of low densities ideal for insoles, midsoles, and outsoles. Even the higher-density polyurethane variants used in outsoles provide tougher material with less weight than other outsole options.

- Chemical & water resistant: Polyurethane is a tough and chemically resistant polymer. Depending on the needs of the application, polyurethane soles can be tailored for greater resistance to either water or chemicals and oils.

- Grip performance: PU outsoles provide excellent grip and prevent slippage, making them ideal for outdoor use in safety shoes, sports shoes, and work shoes.

- Well-established: As the most common sole material in use today, there are countless varieties of polyurethane to fit nearly any application, and the ideal methods of working with the material are widely known and well-established.

Shoes with polyurethane soles provide many benefits to their wearers:

- Comfortable and flexible: Lightweight PU soles are smooth, soft, and elastic, making them a great choice for insoles and midsoles as they conform to the foot. Heavier polyurethane variants are flexible, highly elastic, and widely used in outsoles for comfortable, breathable shoes.

- Cushioning: Thanks to their great elasticity and low density, PU soles offer excellent shock absorption and dampening for use in sports shoes and safety shoes.

- Cost-effective: Polyurethane is a great choice in production, as it is both less expensive to produce and easier to work with than other sole materials. Its durability also provides customers with longer-lasting, more cost-effective footwear.

- Versatile finishes: Polyurethane is available in a wide variety of finishes that enable complete freedom of design through customization options such as coloring, pad printing, and brushing.

- Health benefits: PU soles are hypoallergenic and breathable and are usable in footwear from sandals to sports shoes.

Disadvantages of PU

The main disadvantage of PU soles is their tendency to degrade over long periods of time. As the shoes are stored, moisture in the air reacts with the polymer chains that make up polyurethane in a process called hydrolysis.

This process slowly splits apart the polymer chains over time, making the material more brittle and less flexible. As a result, particularly old PU may disintegrate under stress. Storing shoes with PU soles in areas with high humidity and temperature will accelerate this process, while wearing them regularly will slow this process by exposing them to fresh air.

To increase their lifespan, shoes with PU soles should be stored in a cool, dry place and worn regularly. PU soles may deteriorate more quickly if not stored properly, but they can easily last 5 to 10 years before this occurs—enough that the shoes will usually need to be replaced for another reason long before hydrolysis becomes an issue. Additionally, polyether-based PU soles are a variation that offers greater hydrolysis resistance in applications where the lifespan of the shoe is particularly important.

Are PU soles worth it?

PU soles offer the best mechanical properties on the market for the lowest cost, making them the de facto material of choice for many applications in the footwear industry.

Need a tough polyurethane formulation with great abrasion resistance and demoldability?

Get in touch with our team using the contact form below to learn more about KURARAY LIQUID RUBBER, a polymer additive for PU that improves abrasion resistance, ease of demolding, and productivity.

PU compared to other shoe sole materials

Although other sole materials may be better suited to niche applications, PU soles are a highly flexible option that should usually be considered first.

PU vs. vulcanized rubber

Rubber provides good traction, but PU soles are lighter, less expensive, more flexible, more breathable, and more abrasion-resistant while providing the same slip resistance. Although PU does degrade over time through hydrolysis, the plasticizers in rubber also diffuse out over time, making it hard and brittle.

PU vs. TPU

TPU, or thermoplastic polyurethane, is a thermoplastic elastomer which is suitable for mass production processes such as injection molding. PU refers to thermosetting polyurethane, which does not melt when heated and has high heat resistance.

PU vs. EVA

PU and EVA are both flexible and cushioning materials that are often used in sports shoes, but each has its own strengths and weaknesses. EVA is less expensive, lighter, and easily molds to the foot, but it’s less durable and steadily compresses as it is used, decreasing its cushioning ability over time. PU is much more durable and offers better grip, but it’s slightly more expensive and will break down through hydrolysis over long periods.

PU vs. leather

Although leather soles can last longer if properly cared for, they require much more maintenance and will still deteriorate more quickly than PU soles due to natural wear and tear. PU is often the better choice as it is less expensive, more comfortable, lighter, and can even be styled to look like leather.

Which kinds of shoes benefit from PU soles?

Polyurethane is such a flexible material that it can be used in almost any type of shoe, but a few specific applications make the most use of the light, durable, and comfortable soles that PU provides. Several of these types of shoes, including sports shoes and sandals, are major drivers of rising footwear sales.

Sport shoes

Sport shoes have many requirements for their soles—they need to be durable, comfortable, breathable, light, flexible, shock-resistant, and slip-resistant. PU soles allow sports shoes to achieve all of these qualities at an affordable price without compromising in any areas of performance.

Walking shoes

Shoes intended for daily walking use need to endure excessive amounts of wear and tear while keeping their wearer comfortable. PU soles accomplish these goals, providing a durable, flexible, and water-resistant outsole as well as a light, comfortable insole.

Slippers & sandals

PU soles are commonly used in both cheap and comfortable options, as well as high-end leisure footwear. Their wide variety of formulations, low density, and ability to be used as an insole, midsole, and outsole allow PU soles to fill almost every niche in casual footwear.

Safety shoes

As a sturdy, lightweight material, polyurethane is a natural choice for the soles of safety shoes. Its chemical and water resistance and excellent grip performance make it ideal for the wide variety of situations safety shoes must perform in to protect their wearers.

PU sole manufacturing

Polyurethane soles are produced through a reaction of isocyanates and polyols to form polyurethane polymer. The characteristics of this final polymer are guided by both the molding process used and the concentration of water and expanding agents used during production.

Direct injection process (DIP)

In direct injection, liquid polyurethane is pushed into a closed mold affixed to the shoe, creating a strongly bonded outsole. The pressure used in this process ensures excellent physical properties and a good grain structure.

Pouring

In pouring, liquid polyurethane is poured through a mixing head into an aluminum mold. The mold is then closed to allow the material to set and cool, producing a sole.

PU modification with KURARAY LIQUID RUBBER

To improve abrasion resistance and production efficiency, Kuraray offers KURARAY LIQUID RUBBER, a polyurethane additive ideal for use in both insoles and outsoles.

KURARAY LIQUID RUBBER provides a considerable boost to abrasion resistance when used as an additive in polyurethane formulations. Our internal tests show that before adding L-BR-307, PU has its surface abraded by 82 mg in the Taber abrasion test*. After adding L-BR-307, the PU product is only abraded by 28 mg—a significant improvement to a material that’s already the most durable on the market. The result is an ultra-tough polyurethane for long-lasting shoes, inside and out.

*Test method: JIS K7312, H-22 abrasive wheels, 1 kg load, 1000 rotations.

When used as an additive in polyurethane soles, KURARAY LIQUID RUBBER also improves demoldability. PU formulations that include KURARAY LIQUID RUBBER are easier to remove from their molds, increasing production speed, reducing product loss, and limiting energy waste to make your process smoother and more cost-effective.

KURARAY LIQUID RUBBER is already in use in PU sandals with combined insoles and outsoles, improving the quality and durability of the product for the customer and the efficiency of the manufacturer.

Benefits

- Tougher soles: Increased abrasion resistance for a durable, long-lasting product.

- Cleaner demolding: Quicker production times and fewer product losses.

- Flexibility: Ideal for use in any PU formulation, from insoles to outsoles.

Conclusion

Polyurethane soles are the most popular choice in footwear manufacturing for a reason—they’re a light, durable, flexible, and inexpensive option. Kuraray offers polymer modifiers to support your smooth PU production and the durability of your final product.

Contact