Adhesives, coatings and sealants

As a leading global polymer manufacturer, Kuraray has applied its unique expertise to develop elastomers that offer excellent solutions for a wide range of adhesive, sealant and coating applications. As an industry-recognized expert in the field of multiple polymers including acrylic block co-polymers, polyols, diols, and PVOH, Kuraray has specifically engineered its products to be easy to process and to optimally meet the specific requirements of each application.

The polymers manufactured by Kuraray have a good balance of tack, peel, shear performance and low melt viscosity. They also offer superior adhesion to a variety of substrates and surface textures. Temperature flexibility combined with high heat resistance are further plus points. They are miscible with a wide range of polymers to create excellent adhesives, coatings or sealants. Typical applications include tape and label adhesives, reactive adhesives, industrial and construction adhesives, “noise, vibration and harshness” (NVH) adhesives and sealants, as well as automotive adhesives and sealants.

Adhesives

Tapes and labels

Kuraray products offer tape and label manufacturers a wide range of formulation options. In addition to their outstanding adhesion, they meet even the most challenging requirements of adhesive tape and label applications. Thanks to their strong tack properties, Kuraray’s polymers ensure reliable adhesion even on poorly bondable substrates and at high temperatures.

Protective films

Kuraray has developed a materials technology that can be used in custom protective films. The core chemistry is based on styrenic-block copolymers and is marketed under the brand name SEPTON™& HYBRAR™. The use of these products in protective films allows design flexibility in customizing tack adhesion, excellent adhesion to both polar and non-polar surfaces, and residue-free removal.

Features and benefits

- Adhesion to difficult surfaces, tack / initial tackiness

- Weatherability

- Solvent-free

- Tackiness / processability

- Residual-free, clean removability

- Crosslinking agent-free

- No odor, excellent clarity

- No aging process, quick curing

- Formulation flexibility

- Color stability / transparency, non-yellowing

- Transparency, adjustable coloring

High-performance adhesives

KURARAY LIQUID RUBBER is widely used in adhesive applications, including high-performance automotive adhesives, UV-cured adhesives, PSAs and hot melts. The lower molecular weight grades improve tack and adhesive properties.

Features

- Excellent flexibility

- Tack

- Low shrinkage

- Moisture resistance

Benefits

- Excellent processability

- High stability

- Ideal for flexible electronic applications

Coatings

Sprayable coatings

HYBRAR™ is also suitable for use as a sprayable coating, for example as a component in foamable sound damping sealants. KURARITY™ can be used in various acrylic monomers to adjust the viscosity of the formulation for easy coating. After curing, KURARITY™ can enhance mechanical properties, including tensile and shear strength.

Features

- High strength of the styrenic block copolymers

- Design flexibility

- Residue-free removal

- Good clarity / transparency

- Excellent weatherability

Benefits

- Surface protection

- Customizable tack adhesion for different surface finishes (e.g. embossed or non-embossed)

- Excellent tack adhesion

- Direct processing without previous compounding

- Lower overall structure costs

- Favorable economics of the co-extrusion process

KURARITY™ for hot-melt adhesives

Grades with low PMMA content provide good adhesive properties which are suitable for various clean and environmentally friendly adhesives without the use of solvents and tackifiers. They are particularly suitable for hot-melt adhesive materials. Also, with its superior processability, it is possible to co-extrude adhesive layers of KURARITY™ to other plastic components, which simplifies the manufacturing process and reduces costs.

Features

- Self-adhesion

- Solvent-free

- Minimal residuals on the surface of the substrate

- Extremely low migration without tackifier

- Excellent clarity

- Excellent weatherability and no hydrolysis degradation

Benefits

- No drying and curing process necessary

- Low VOC and ultimately less odor without solvent and residual monomer

- No odor

- Clean surface

- Perfect for transparent substrates

- Durability

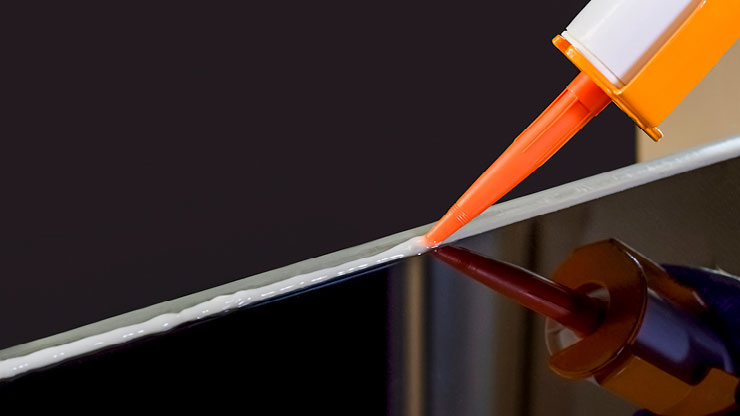

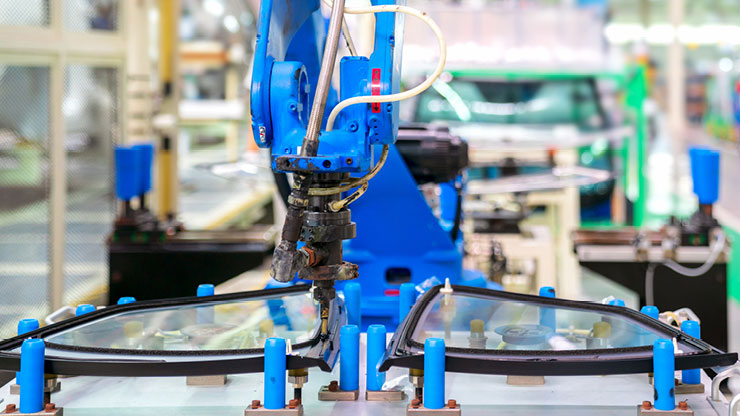

Sealants

Automotive sealants

The various grades of SEPTON™ and KURARITY™ deliver outstanding adhesive properties combined with improved temperature and weather resistance for automotive sealants. Certain products can be foamed and cured during the paint curing process for added damping performance. For automotive adhesives, Kuraray has developed selected Kuraray Liquid Rubber grades, high-viscosity synthetic rubbers, with different functionalities to improve adhesion to metal surfaces as well as to tailor damping performance. KURARAY LIQUID RUBBER also improves adhesion to oily surfaces and is used where low-temperature performance and quick curing are required. With LIQUID FARNESENE RUBBER, Kuraray even offers a bio-based alternative for automotive sealants.

Features

- Excellent tensile properties, compression set and oil resistance

- Good surface smoothness

- Narrow molecular weight distribution

- Minimal residuals/low VOCs

- Broad range of glass transition temperatures

Benefits

- Improved quality

- Tailored performance over a wide temperature range

- Noise reduction

- Multifunctional sealant

- Wear resistance

Contact